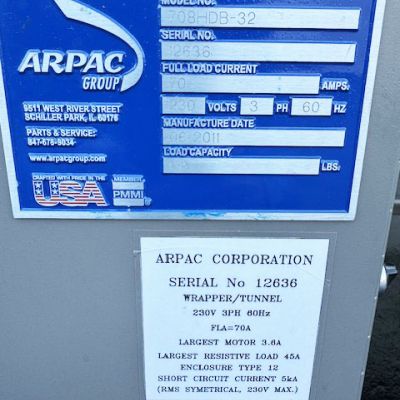

ARPAC Shrink Bundler Model 708HBD-32

Equipment Specifications

Manufacturer | ARPAC Brand Packaging Solutions |

Model | 708HBD-32 |

Serial Number | 12636 |

Condition | used |

Optimize Your Packaging Line with the ARPAC 708HBD-32 Shrink Bundler

Elevate your packaging capabilities with the ARPAC 708HBD-32, a versatile shrink bundler designed to meet the dynamic demands of the health and beauty industry. Recognized for its compact design and high efficiency, this used ARPAC shrink bundler is an ideal choice for businesses looking to enhance their packaging processes.

Key Features of the ARPAC 708HBD-32 Shrink Bundler

- Dual Lane Configuration: Capable of handling up to 50 bundles per minute, the 708HBD-32 maximizes productivity by operating in either dual lane for increased throughput or single lane for larger bundles.

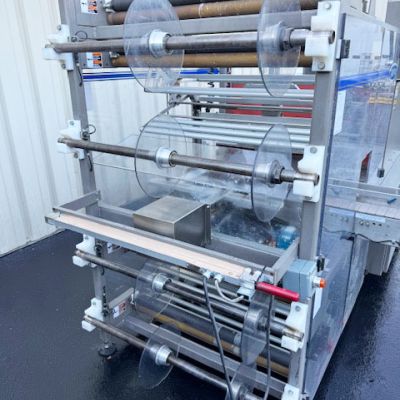

- Innovative Design: Features motorized pulleys instead of traditional drives and chains, resulting in cleaner, safer operations with a slimmer machine profile.

- Flexible Operation: Comes with a 32-inch wide seal bar and powered infeed conveyor, accommodating a wide range of product sizes and packaging needs.

Built for Performance and Ease of Use

The ARPAC 708HBD-32 shrink bundler boasts a host of features designed to simplify operations while maintaining rigorous production standards:

- Heavy-duty Construction: Durable single-frame steel construction and CNC machined components ensure reliable around-the-clock operation.

- User-Friendly Interface: Equipped with an ARPAC operator interface featuring an alphanumeric display and self-diagnostics for quick troubleshooting and minimal downtime.

- Low Maintenance Requirements: The conveyor belts do not require tracking adjustments, and the motorized pulleys eliminate the need for chain drive maintenance.

Advanced Safety and Convenience Features

Safety and operational convenience are at the forefront of the ARPAC 708HBD-32 design:

- Safety Interlocks: Equipped with interlocking access doors to ensure operator safety during machine operation.

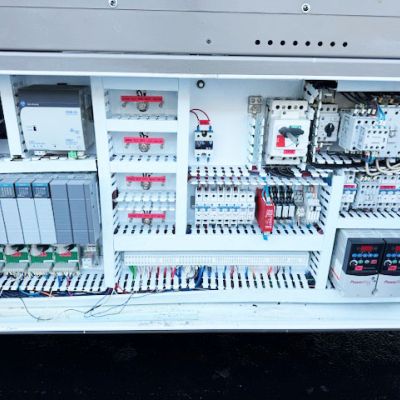

- Comprehensive Control Panel: Includes an operation control panel with emergency stop and stack light indicators to monitor system status actively.

Why Choose a Used ARPAC Shrink Bundler?

Choosing this used ARPAC 708HBD-32 from CWR Resources means investing in a machine that combines speed, versatility, and reliability. This system is particularly suitable for manufacturers requiring a robust packaging solution that can seamlessly integrate into existing production lines, offering immediate enhancements in packaging speed and quality.

Details

- Right-Angle Infeed

- 32“ Wide Seal Bar

- Powered Infeed Conveyor 7.5” Wide x 102” Long

- 7.5” Wide Plastic Table Top Infeed Conveyor Belt

- 34” Wide Plastic Heat Tunnel Belt

- Heat Tunnel Opening 60” L x 40” W x 11” H

- Allen Bradley SLC 5/03 Programmable Logic Controller

- Allen Bradley PowerFlex4 Variable Speed Drives

- Stack Light Indicator

- Operation Control Panel with E-Stop

- Safety Interlocking Access Doors

- Electrical 230 Volt, 3 Ph, 60 Hz, 70 FLA,

- (6) Threaded Leg Levelers

- Includes Operation and Maintenance Manual

- Overall Dimensions: 170” L x 48” W x 72” H (104” Wide with Infeed Conveyor)

- Compact single-frame steel construction

- Heavy-duty system for around-the-clock operation

- Laser cut and CNC machined components for maximum precision and strength

- ARPAC operator interface featuring an alphanumeric message display and self-diagnostics

- Simple setup and tool-less changeovers for ease of use and minimal downtime

- Low-maintenance conveyor belts do not require tracking adjustments

- Motorized pulleys eliminate chain drives and operate more cleanly, with reduced maintenance cost and less noise

- Single-stage right-angle infeed conveyor with plastic belt

- Bridge plate for small product transfer

- Conveyor elevation 35″ +2/-0 for easy integration with existing equipment

- Powered film unwind

- NEMA 12 electrical cabinet and controls

- Low film alert warns that a film changeover will soon be necessary

- Quick-change seal bar with military-type quick disconnect and replaceable plasma-coated inserts

- Product hold-down for light products

- Top and bottom film racks accommodate four 14″ diameter rolls of film

- Easy-to-service air cylinders

- Separate pop-up guide and multiple ram stroke programming for multi-row collation

- Levelers for uneven floors

- Speed: Up to 40 packages per minute

- Air: 80 psi, 8 SCFM

- Product Range

- Minimum 3/4” W x 3/4” L x 1/2” H

- Maximum 6” W x 11” L x 8” H

- Package Range

- Minimum 3.5” W x 3/4” L x 1/2” H

- Maximum 10.5” W x 10” L x 8” H

- Film Specifications

- Roll Diameter: 14″ maximum with 3” core

- Gauge: 1.25-2 mil

- Roll Width: Up to 14″ (dual roll)

- Type: Polyethylene, clear or random print

Similar Equipment Listings

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging

-

Filling Line with Pacific 8-Head Inline Piston Filler and Zalkin Single Head Capper

Cappers, Filling Machines, Packaging, Piston Fillers

-

MRM (Cozzoli) 8 Head Rotary Piston Filler

Filling Machines, Packaging, Piston Fillers

-

Kaps-All A6 Spindle Inline Screw Capper

Cappers, Packaging

-

Palace Packaging Empty Bottle Unscrambler with Hopper-Elevator CB-42-PB4 / H-25

Bottle Unscramblers, Packaging

-

Eagle Case Sealer Taper T500

Case Sealers, Packaging

-

Marburg Neck Bander M-500 & Heat Tunnel

Cappers, Neck Bander Machines, Packaging

-

Wexxar Bel 505 Case Former Pack Station & 252 Case Sealer Taper

Case Erectors, Case Sealers, Packaging

-

Angelus 60L Can Seamer

Can Seamers, Packaging

-

Holmatic PR-1 Cup Filling and Sealing System

Cup Fillers, Filling Machines, Packaging

-

Belcor 250SS Top & Bottom Case Sealer

Case Sealers, Packaging

-

Pearson Model CE25 Hot Glue Case Erector

Case Erectors, Packaging

-

Texwrap Model T2011SSCRR Stainless Steel Shrink Wrapper

Packaging, Shrink Wrap Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging

-

Matrix Pro Series Vertical Form Fill Seal Machine

Form Fill Seal Machines, Packaging

-

Mettler Toledo Safeline PowerPhase Metal Detector

Food Metal Detectors, Packaging

-

Weigh Right Linear Scale

Industrial Scales, Packaging

-

SWF Tray Former 1T4

Packaging, Tray Formers

-

Mettler Toledo Safeline Combination Metal Detector and Checkweigher

Checkweighers, Food Metal Detectors, Packaging

-

Shanklin Shrink Tunnel T-62SS

Packaging, Shrink Wrap Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging

-

All-Fill Model SHA-600 Single Head Inline Powder Filler

Filling Machines, Packaging, Powder Filling Machines

-

All-Fill Model B400 Single Head Inline Powder Filler

Filling Machines, Packaging, Powder Filling Machines

-

Sato Print and Apply Bar Code Labeler

Labeling Machines, Packaging

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging

-

Hayssen Stainless Steel Ultima Vertical Form Fill Seal

Form Fill Seal Machines, Packaging

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging

-

Ohlson 14 Head Stainless Steel Rotary Scale

Industrial Scales, Packaging

-

E-PAK Waterfall Cap Sorter Elevator Feeder

Cap Elevators, Packaging

-

Canco Can Seamer Model 422-1E-00 Set for 300 DIA

Can Seamers, Packaging

-

Canco Can Seamer Model 006 Set for 401 DIA

Can Seamers, Packaging

-

Canco Can Seamer Model 08

Can Seamers, Packaging

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging

-

FMC 12G Volumetric Filler Set for 603 DIA

Filling Machines, Packaging, Volumetric Filling Machines

-

Apex 12-Head Inline Filler Model POF-12

Filling Machines, Gravity/Pressure Fillers, Packaging

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging