Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Equipment Specifications

Manufacturer | Elmar |

Model | RPE-736/16T |

Location | Batavia, IL. |

Year | 2008 |

Serial Number | EM07-7022 |

Stock Number | 00001 |

Condition | used |

36 Head Rotary Piston Filler | 67 ounce pistons |

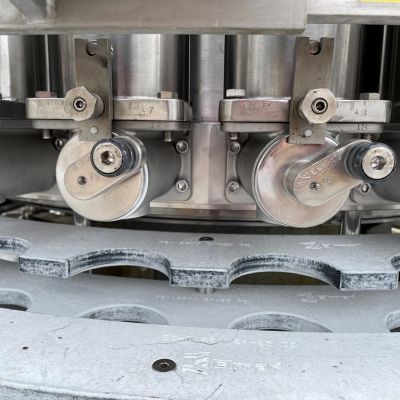

The Elmar RPE-736/16T 36-Head Rotary Piston Filler with a 16-Head Capper is a comprehensive solution for high-speed, precise filling and capping operations. Featuring a 36-station Elmar filler turret and a Fowler Zalkin 16-head “Pick and Place” capping turret, this machine is engineered for exceptional performance and flexibility. Its advanced design includes 3-3/4″ diameter super extended cylinders for a maximum fill range of up to 67 fluid ounces and stainless steel “Dome Style” pistons with PTFE wear rings for durability and precision. Equipped with motorized volume adjustment, quick change feed screw, and toolless change parts, this filler/capper combination ensures quick setup and changeover, maximizing production efficiency.

The inclusion of a central lubrication cluster and a complete electronic control system with Allen-Bradley PLC and InverterDrive System facilitates seamless operation and maintenance. The Fowler/Zalkin capping turret, specifically designed for 63 mm screw-on closures, integrates advanced features such as hysteresis magnetic clutch heads and a quick change “Peg & Ring” cap transfer system, enhancing the machine’s capability to handle a wide range of container sizes and materials at speeds tailored to each product specification. This Elmar filler is not just a machine; it’s a turnkey solution for businesses looking to elevate their packaging line’s productivity and reliability.

- 3-3/4″ Diameter super extended cylinders (max fill range 67 fluid ounces)

- 3-3/4″ diameter stainless steel “dome style” pistons with PTFE wear rings and “0” ring

- Motorized volume adjustment

- Adjustable container rails with replaceable UHMW wear surface

- Quick change feed screw – toolless

- Change parts – toolless

- Powered bowl height adjustment (3-15/16″ to 9-15/16″), for instant height change-over

- Central lubrication cluster – Lincoln Automatic Lubrication System (manual pump)

- Complete electronic control system with A-B 5/05 PLC and operator station with Allen-Bradley inverter drive system, 480v/3ph/60hz

- The Elmar Industries Inc. Filler control system is a programmable logic controller (PLC) based control system. The basic unit controls filler speed, fill volume, and the no container no filler (NCNF) trip mechanism

- Fowler/Zalkin 16-head “pick and place” capping turret (PCD 498 mm) to mount on an Elmar filler monoblock. This turret is equipped for 63 mm, screw-on closures to pet bottles, at a rate of applied closures per minute. This machine is equipped as follows:

- Set of sixteen (16) Zalkin BH-3 Hysteresis magnetic clutch heads for screw-on closures requiring an application torque of 12-36″ pounds +-10%

- Heads are equipped for use with quick change chucks for cap handling and application

- Set of sixteen (16) quick change chucks for the 63 mm screw-on closure. Quick change chucks use a ball and ring assembly for quick release from, and remounting to, the capping head

- Telescoping cap chute suitable for the 63 mm closures and suitable for mating with “nose over” chute

- Cap chute steam cloud box (15″ x 3′ x 4 long) and cap transfer steam manifold, supplied to heat cap before application

- Quick Change “Peg & Ring” cap transfer system for smooth closure pick-off from the discharge of the cap chute and transfer to the capping heads. Transfer system is equipped with quick change quick release features to allow for no tools change-over. Transfer system includes sensors for no bottle/no cap control

- Self-contained elevating system for adjusting the height of the capping turret as required by differing heights of containers. Safeties are included to prevent travel beyond machine limits. Minimum 4″, maximum 12″ height of container.

Designed to run the following containers and speeds (nominal CPM):

- 15 oz Glass / 300

- 23/25 oz Glass / 300

- 50 oz Glass / 160

- 24 oz PET / 160

- 48 oz PET / 160

- 64 oz PET / 160

Similar Equipment Listings

-

Polypack TR-35 Automatic Tray Former and Packer

Packaging Equipment, Tray Formers

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

ARPAC Shrink Bundler 708HBD-32

Packaging Equipment, Shrink Wrap Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

Safeline Metal Detector Conveyor-Mounted

Food Metal Detectors, Packaging Equipment

-

3M Case Sealer 800 ASB (Type 29600) Adjustable Top and Bottom

Case Sealers, Packaging Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All AU-6 Empty Bottle Unscrambler

Bottle Unscramblers, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

ARPAC Shrink Bundler Model 708HBD-32

Packaging Equipment, Shrink Wrap Equipment

-

Marburg Neck Bander M-500 & Heat Tunnel

Cappers, Neck Bander Machines, Packaging Equipment

-

Wexxar Bel 505 Case Former Pack Station & 252 Case Sealer Taper

Case Erectors, Case Sealers, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Matrix Pro Series Vertical Form Fill Seal Machine

Form Fill Seal Machines, Packaging Equipment

-

Mettler Toledo Safeline PowerPhase Metal Detector

Food Metal Detectors, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Mettler Toledo Safeline Combination Metal Detector and Checkweigher

Checkweighers, Food Metal Detectors, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

All-Fill Model B400 Single Head Inline Powder Filler

Filling Machines, Packaging Equipment, Powder Filling Machines

-

Sato Print and Apply Bar Code Labeler

Labeling Machines, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment