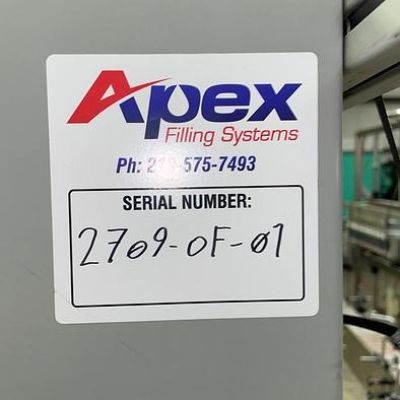

Apex 12-Head Inline Filler Model POF-12

Equipment Specifications

Manufacturer | Apex Filling Systems |

Location | Batavia, IL. |

Stock Number | 00013 |

Condition | used |

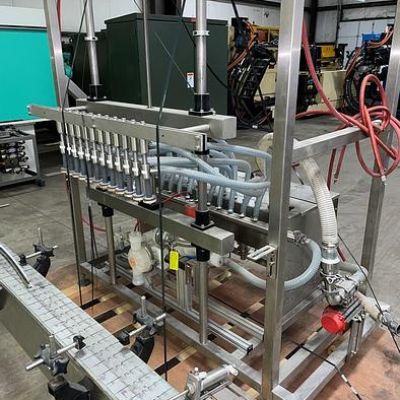

The Apex Filling Systems 12-Head Inline Filler Model POF-12 exemplifies the pinnacle of precision in liquid filling technology. Utilizing the “fill to level” principle, this used stainless steel filler is designed for pressure overflow filling, ensuring each container reaches a consistent visual fill level. This method is ideal for handling a wide variety of products and container types, making the POF-12 a versatile choice for diverse industries.

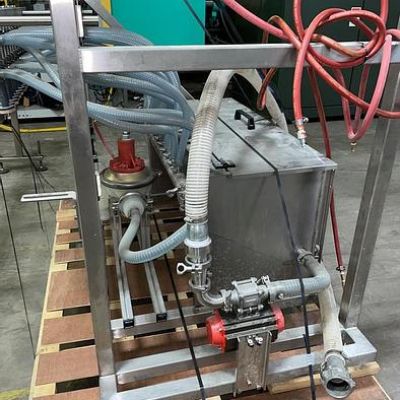

Equipped with state-of-the-art features such as a touch screen PLC control package, sensor package, and a stainless steel centrifugal pump for product pressure delivery, the system ensures seamless operation. The inclusion of a heavy-duty stainless steel frame, conveyor system, and automation package with dual pin escapement indexing further enhances its functionality. The system’s efficiency is boosted by its 20-gallon surge/supply tank and fully adjustable settings to accommodate different container sizes, ensuring maximum throughput and operational flexibility.

- Fill to level principle, designed for pressure overflow filling

- 300 series stainless steel mechanical filling nozzle on each fill head

- Sensor package

- Stainless steel head centrifugal pump for product pressure delivery

- Variable speed control conveyor system

- 15′ long delrin conveyor belt

- Powered height adjustment

- Automation package with dual pin escapement indexing

- 20-gallon stainless steel surge/supply tank mounted on a heavy-duty stainless steel frame with sanitary inlet/outlet connections

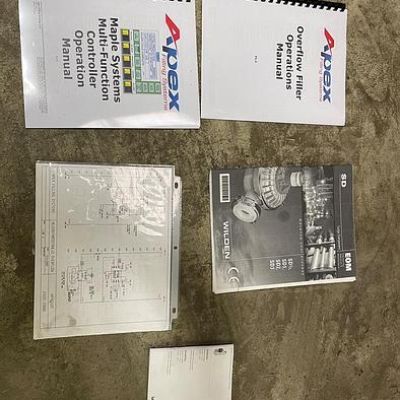

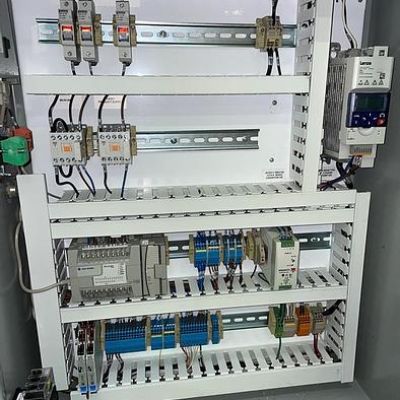

- Color touch screen interface PLC control package

- On-screen help guides

- Job/recipe memory

- Manual jog mode

- Complete variable operational timer controls

- Plc interface with real-time input/output display

- Management screen including real-time machine production rates

- Troubleshooting assistance with on-screen error messages

Similar Equipment Listings

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging

-

Filling Line with Pacific 8-Head Inline Piston Filler and Zalkin Single Head Capper

Cappers, Filling Machines, Packaging, Piston Fillers

-

MRM (Cozzoli) 8 Head Rotary Piston Filler

Filling Machines, Packaging, Piston Fillers

-

Kaps-All A6 Spindle Inline Screw Capper

Cappers, Packaging

-

Palace Packaging Empty Bottle Unscrambler with Hopper-Elevator CB-42-PB4 / H-25

Bottle Unscramblers, Packaging

-

ARPAC Shrink Bundler Model 708HBD-32

Packaging, Shrink Wrap Equipment

-

Eagle Case Sealer Taper T500

Case Sealers, Packaging

-

Marburg Neck Bander M-500 & Heat Tunnel

Cappers, Neck Bander Machines, Packaging

-

Wexxar Bel 505 Case Former Pack Station & 252 Case Sealer Taper

Case Erectors, Case Sealers, Packaging

-

Angelus 60L Can Seamer

Can Seamers, Packaging

-

Holmatic PR-1 Cup Filling and Sealing System

Cup Fillers, Filling Machines, Packaging

-

Belcor 250SS Top & Bottom Case Sealer

Case Sealers, Packaging

-

Pearson Model CE25 Hot Glue Case Erector

Case Erectors, Packaging

-

Texwrap Model T2011SSCRR Stainless Steel Shrink Wrapper

Packaging, Shrink Wrap Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging

-

Matrix Pro Series Vertical Form Fill Seal Machine

Form Fill Seal Machines, Packaging

-

Mettler Toledo Safeline PowerPhase Metal Detector

Food Metal Detectors, Packaging

-

Weigh Right Linear Scale

Industrial Scales, Packaging

-

SWF Tray Former 1T4

Packaging, Tray Formers

-

Mettler Toledo Safeline Combination Metal Detector and Checkweigher

Checkweighers, Food Metal Detectors, Packaging

-

Shanklin Shrink Tunnel T-62SS

Packaging, Shrink Wrap Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging

-

All-Fill Model SHA-600 Single Head Inline Powder Filler

Filling Machines, Packaging, Powder Filling Machines

-

All-Fill Model B400 Single Head Inline Powder Filler

Filling Machines, Packaging, Powder Filling Machines

-

Sato Print and Apply Bar Code Labeler

Labeling Machines, Packaging

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging

-

Hayssen Stainless Steel Ultima Vertical Form Fill Seal

Form Fill Seal Machines, Packaging

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging

-

Ohlson 14 Head Stainless Steel Rotary Scale

Industrial Scales, Packaging

-

E-PAK Waterfall Cap Sorter Elevator Feeder

Cap Elevators, Packaging

-

Canco Can Seamer Model 422-1E-00 Set for 300 DIA

Can Seamers, Packaging

-

Canco Can Seamer Model 006 Set for 401 DIA

Can Seamers, Packaging

-

Canco Can Seamer Model 08

Can Seamers, Packaging

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging

-

FMC 12G Volumetric Filler Set for 603 DIA

Filling Machines, Packaging, Volumetric Filling Machines

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging