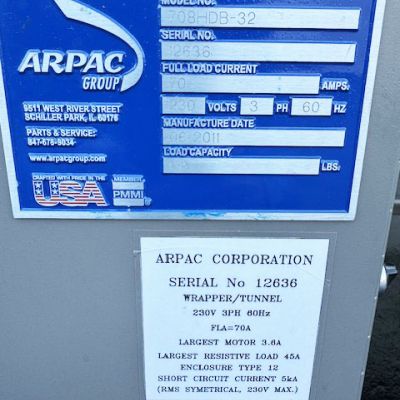

ARPAC Shrink Bundler Model 708HBD-32

Equipment Specifications

Manufacturer | ARPAC |

Model | 708HBD-32 |

Serial Number | 12636 |

Condition | used |

Versatile Multi-Industry Packaging Solution

Transform your packaging operations with this proven ARPAC 708HBD-32 shrink bundler, engineered to deliver consistent performance across food and beverage, pharmaceutical, and chemical processing applications. This robust system combines precision engineering with operational flexibility, making it an excellent investment for facilities requiring reliable, high-throughput packaging capabilities.

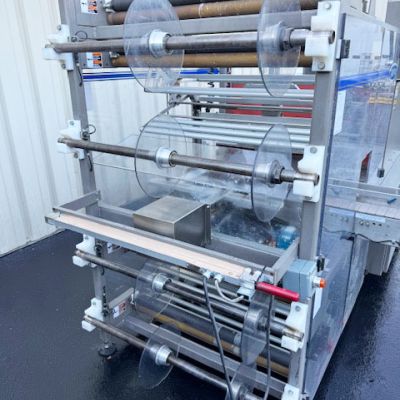

Advanced Multi-Industry Shrink Bundling Technology

The ARPAC 708HBD-32 delivers exceptional versatility with its dual-lane configuration, processing up to 40 packages per minute while accommodating diverse product ranges. Its innovative motorized pulley system eliminates traditional chain drives, resulting in cleaner operation, reduced maintenance costs, and quieter performance—critical advantages for multi-shift production environments across various industries.

Professional ARPAC Packaging Equipment Design

This system’s comprehensive feature set includes a 32-inch wide seal bar with quick-change capability and military-type quick disconnect for rapid changeovers. The right-angle infeed configuration with plastic belt conveyor ensures smooth product handling, while the spacious heat tunnel opening (60″L x 40″W x 11″H) accommodates products ranging from small pharmaceutical vials to larger food containers.

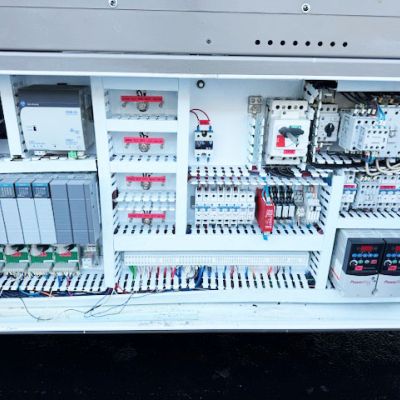

Intelligent Control and Safety Systems

Advanced automation capabilities feature Allen Bradley SLC 5/03 PLC control with PowerFlex4 variable speed drives, providing precise operation control. The comprehensive safety package includes interlocking access doors, emergency stop functionality, and stack light indicators, ensuring compliance with stringent industry safety standards across food, pharma, and chemical sectors.

Built for Continuous Operation Excellence

Constructed with single-frame steel architecture and CNC-machined components, this shrink bundler delivers reliable around-the-clock performance. The low-maintenance design features tracking-free conveyor belts and tool-less changeovers, minimizing downtime while maximizing productivity. Six threaded leg levelers ensure stable operation on any factory floor.

Ready to enhance your packaging efficiency across multiple product lines? Contact CWR Resources today to discuss how this versatile ARPAC shrink bundler can streamline your operations and improve packaging consistency.

Details

- Configuration: Dual Lane Shrink Bundler with Right-Angle Infeed

- Production Rate: Up to 40 packages per minute Seal Bar: 32″ Wide Quick-Change Design with Military-Type Quick Disconnect

- Conveyor Specifications:

- Powered Infeed: 7.5″ Wide x 102″ Long

- Infeed Belt: 7.5″ Wide Plastic Table Top

- Heat Tunnel Belt: 34″ Wide Plastic

- Heat Tunnel Opening: 60″ L x 40″ W x 11″ H

- Control Systems:

- Allen Bradley SLC 5/03 Programmable Logic Controller

- Allen Bradley PowerFlex4 Variable Speed Drives

- Stack Light Indicator System

- Operation Control Panel with Emergency Stop

- Low Film Alert Warning System

- Safety Features: Safety Interlocking Access Doors Electrical: 230 Volt, 3 Ph, 60 Hz, 70 FLA Air Requirements: 80 psi, 8 SCFM

- Product Range:

- Minimum: 3/4″ W x 3/4″ L x 1/2″ H

- Maximum: 6″ W x 11″ L x 8″ H

- Package Range:

- Minimum: 3.5″ W x 3/4″ L x 1/2″ H

- Maximum: 10.5″ W x 10″ L x 8″ H

- Film Specifications:

- Roll Diameter: 14″ maximum with 3″ core

- Gauge: 1.25-2 mil

- Roll Width: Up to 14″ (dual roll)

- Type: Polyethylene, clear or random print

- Structural Features:

- Compact Single-Frame Steel Construction

- Laser Cut and CNC Machined Components

- Heavy-Duty Design for Around-the-Clock Operation

- (6) Threaded Leg Levelers for Floor Adjustment

- Dimensions: 170″ L x 48″ W x 72″ H (104″ Wide with Infeed Conveyor)

- Conveyor Elevation: 35″ +2/-0 for Easy Integration with Existing Equipment

- Documentation: Operation and Maintenance Manual Included

- Advanced Features:

- Powered Film Unwind System

- NEMA 12 Electrical Cabinet and Controls

- Replaceable Plasma-Coated Seal Bar Inserts

- Product Hold-Down for Light Products

- Top and Bottom Film Racks (Four 14″ Diameter Rolls)

- Easy-Service Air Cylinders

- Pop-Up Guide with Multi-Row Collation Programming

- Tool-Less Changeovers for Minimal Downtime

- Low-Maintenance Conveyor Belts (No Tracking Adjustments Required)

- Motorized Pulleys (Cleaner Operation, Reduced Maintenance)

- Bridge Plate for Small Product Transfer

Similar Equipment Listings

-

Polypack TR-35 Automatic Tray Former and Packer

Packaging Equipment, Tray Formers

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

ARPAC Shrink Bundler 708HBD-32

Packaging Equipment, Shrink Wrap Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

Safeline Metal Detector Conveyor-Mounted

Food Metal Detectors, Packaging Equipment

-

3M Case Sealer 800 ASB (Type 29600) Adjustable Top and Bottom

Case Sealers, Packaging Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All AU-6 Empty Bottle Unscrambler

Bottle Unscramblers, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

Marburg Neck Bander M-500 & Heat Tunnel

Cappers, Neck Bander Machines, Packaging Equipment

-

Wexxar Bel 505 Case Former Pack Station & 252 Case Sealer Taper

Case Erectors, Case Sealers, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Matrix Pro Series Vertical Form Fill Seal Machine

Form Fill Seal Machines, Packaging Equipment

-

Mettler Toledo Safeline PowerPhase Metal Detector

Food Metal Detectors, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Mettler Toledo Safeline Combination Metal Detector and Checkweigher

Checkweighers, Food Metal Detectors, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

All-Fill Model B400 Single Head Inline Powder Filler

Filling Machines, Packaging Equipment, Powder Filling Machines

-

Sato Print and Apply Bar Code Labeler

Labeling Machines, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging Equipment, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment