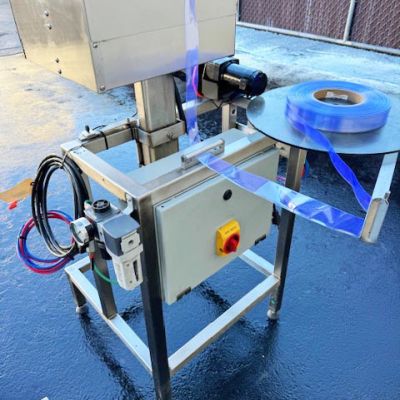

Marburg Neck Bander M-500 & Heat Tunnel

Equipment Specifications

Manufacturer | Marburg Industries |

Model | AUTOCAPSEALER M-500 |

Serial Number | 9121 |

Condition | used |

High-Efficiency Shrink Sleeving

Now available the Marburg Neck Bander M-500 & Heat Tunnel, a robust and highly efficient solution tailored for precision neck banding applications. As part of our commitment to delivering top-tier packaging equipment, CWR Resources is proud to offer this used, shop-tested Marburg system, renowned for its operational excellence and reliability. Designed by Marburg Industries, Inc. of Vista, CA, a leader in the packaging industry, this system offers unparalleled performance for your sleeving needs.

Key Features of Marburg Neck Bander / Shrink Sleever – Model M-500

- Versatility in Material Handling: The M-500 can manage materials ranging from 25mm to 90mm layflat, accommodating a variety of band lengths from 0.5” to 7” and thicknesses from 40 to 70 microns.

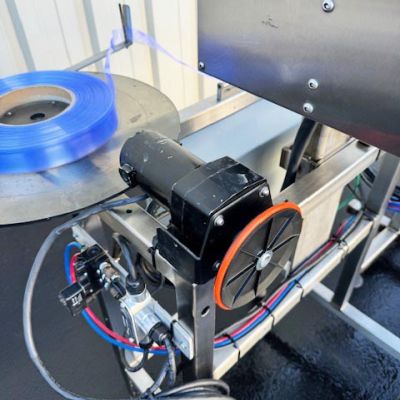

- High-Speed Operation: Capable of reaching speeds up to 200 bottles per minute, this neck bander enhances your production line’s efficiency without compromising on quality.

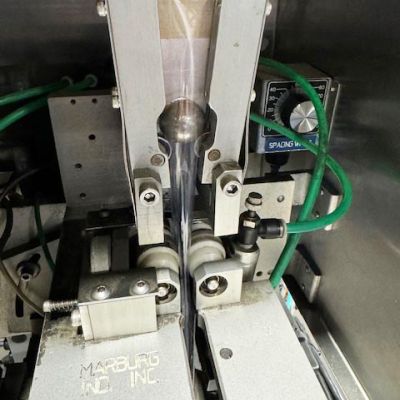

- Precision Application: Includes vertical perforation options and a powered container spacer indexing wheel, which ensures precise placement and consistent performance.

- Change Part Flexibility: Comes equipped with four existing change part bullets (33mm, 42mm, 44mm, 49mm), allowing quick adjustments and versatility across multiple product lines.

Key Features of Marburg Electric Heat Shrink Tunnel – Model CR6000-ST

- Efficient Heating Mechanism: Utilizes an electric heat type tunnel with flow-through ventilation for effective shrinkage of bands.

- Compact and Robust Design: Features a stainless steel base and compact dimensions (Overall Tunnel Length: 22 inches), making it ideal for operations with limited space.

- Innovative Features: Equipped with an automatic pneumatic lift mechanism that raises the heat tunnel when not in use, enhancing operational safety and convenience.

System Specifications and Integration

- Dimensions and Installation: The Sleever measures 36” L x 36” W x 60” H, while the tunnel has an opening of 2” wide x 2.5” tall, easily integrating over your existing conveyor systems.

- Power Requirements: Sleever electrical is 120 Volt, 1 Ph, 60 Hz, 7 Amps with 24 VDC controls. The tunnel operates on 220 Volt, 1 Ph, 60 Hz.

- Support and Stability: Both units are supported by stainless steel stands with leveler legs to ensure stability during operation.

Similar Equipment Listings

-

Polypack TR-35 Automatic Tray Former and Packer

Packaging Equipment, Tray Formers

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

ARPAC Shrink Bundler 708HBD-32

Packaging Equipment, Shrink Wrap Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

Safeline Metal Detector Conveyor-Mounted

Food Metal Detectors, Packaging Equipment

-

3M Case Sealer 800 ASB (Type 29600) Adjustable Top and Bottom

Case Sealers, Packaging Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All AU-6 Empty Bottle Unscrambler

Bottle Unscramblers, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

Palace Packaging Empty Bottle Unscrambler with Hopper-Elevator CB-42-PB4 / H-25

Bottle Unscramblers, Packaging Equipment

-

ARPAC Shrink Bundler Model 708HBD-32

Packaging Equipment, Shrink Wrap Equipment

-

Wexxar Bel 505 Case Former Pack Station & 252 Case Sealer Taper

Case Erectors, Case Sealers, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Matrix Pro Series Vertical Form Fill Seal Machine

Form Fill Seal Machines, Packaging Equipment

-

Mettler Toledo Safeline PowerPhase Metal Detector

Food Metal Detectors, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Mettler Toledo Safeline Combination Metal Detector and Checkweigher

Checkweighers, Food Metal Detectors, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

All-Fill Model B400 Single Head Inline Powder Filler

Filling Machines, Packaging Equipment, Powder Filling Machines

-

Sato Print and Apply Bar Code Labeler

Labeling Machines, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging Equipment, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment