Seal-A-Tron AS-2024-AC Automatic L-Bar Sealer

Equipment Specifications

Manufacturer | Seal-A-Tron |

Model | AS-2024-AC |

Location | North Dakota |

Year | 2018 |

Serial Number | AS2024AC1822 |

Condition | used |

Automatic L-Bar Sealer for High-Volume Shrink Wrap Operations

This used, automatic Seal-A-Tron L-Bar Sealer AS-2024-AC represents an exceptional opportunity for operations seeking to increase shrink wrap packaging efficiency and consistency. Manufactured in 2018 by Seal-A-Tron Corporation, this automatic sealer features advanced electronic seal stroke technology that eliminates the need for compressed air—reducing maintenance requirements while delivering reliable, precise sealing performance. Built for medium to high-volume production environments, this machine has logged 336,941 cycles, demonstrating its proven durability in demanding packaging applications.

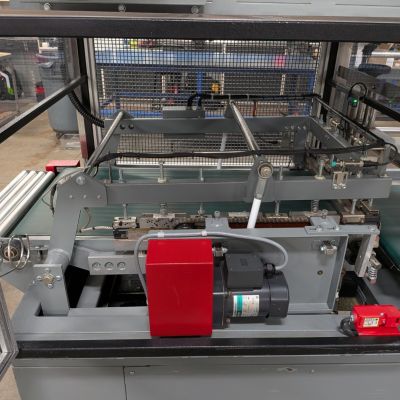

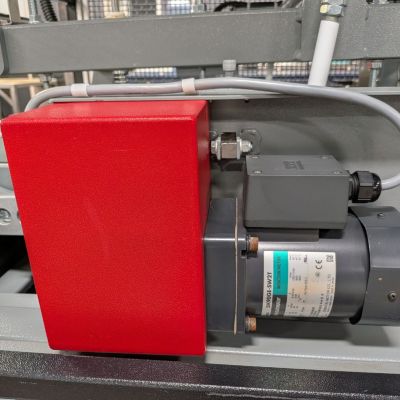

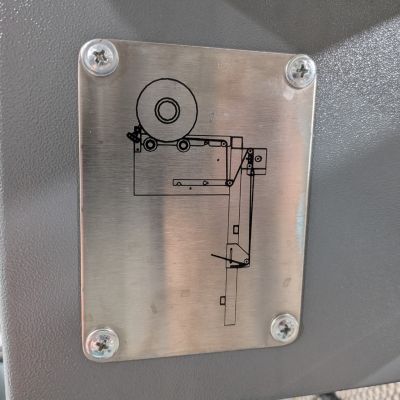

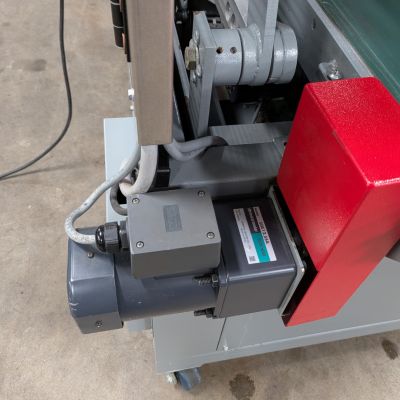

Electronic Seal Stroke Technology and Shrink Film Sealing Capabilities

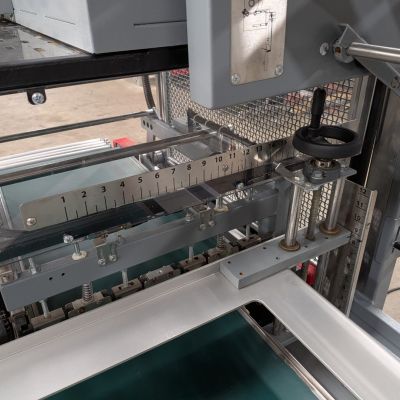

The AS-2024-AC features Seal-A-Tron’s innovative electronic seal stroke system, a significant advancement over traditional pneumatic L-bar sealers. This all-electric design provides quieter operation, lower maintenance costs, and more consistent sealing compared to air-powered alternatives. The 20-inch wide by 23-inch long seal bar accommodates a wide range of product sizes, with a maximum height capacity of 9 inches and 30-inch web width. Whether you’re packaging retail products, food items, electronics, or industrial components, this L-bar sealer creates professional, tamper-evident packages with crystal-clear centerfold shrink film.

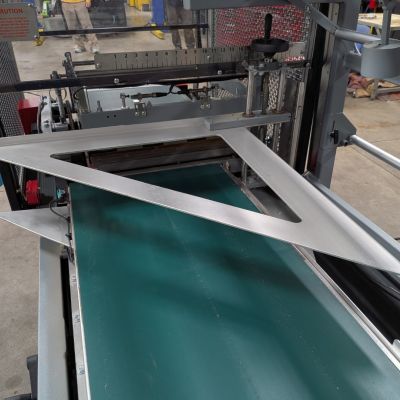

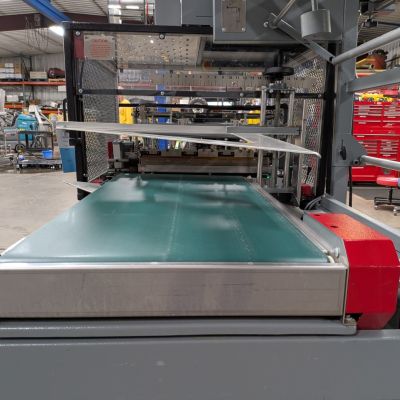

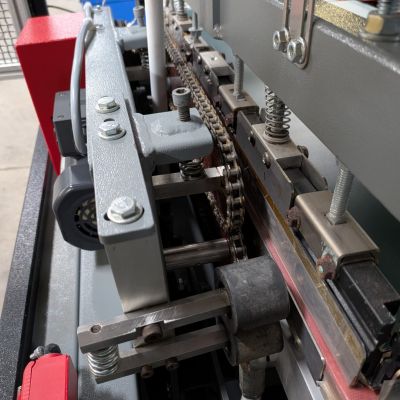

Integrated Conveyor System for Automated Shrink Wrap Packaging

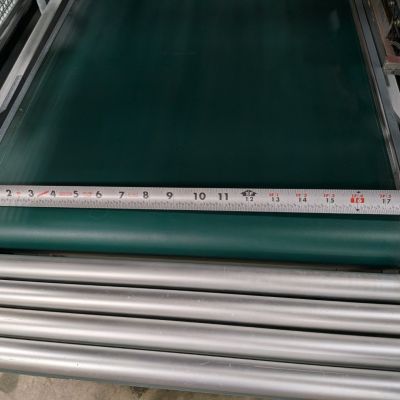

This complete shrink wrap sealing system includes both infeed and discharge conveyors for streamlined material handling. The 38-inch long infeed vinyl belt conveyor (17.75 inches wide) feeds products smoothly into the sealing area, while the 36-inch retracting discharge conveyor automatically transfers sealed packages away from the machine. This automated workflow reduces manual handling, increases throughput, and ensures consistent package positioning for optimal seal quality. The system is ideal for integration with shrink tunnels to create complete automated shrink wrapping lines.

Panasonic Touchscreen Controls and PLC Programming

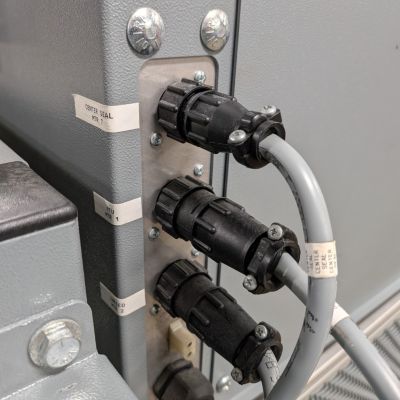

Advanced Panasonic touchscreen controls paired with an AFPX-EFPO PLC provide intuitive operation and precise process control. The color HMI screen allows operators to easily adjust variable speed controls, configure product staging, and modify seal parameters without extensive training. The motorized center seal adjustment ensures proper film positioning across different product sizes, while the horizontal photo eye and proximity sensors deliver reliable package detection. The auto-reverse feature accommodates taller packages, and the convenient film scrap take-up system simplifies waste management during production runs.

Durable Construction for Commercial Packaging Equipment

Built with robust mild steel construction and mounted on casters for flexible positioning, this L-bar sealer is designed for long-term industrial use. The V-grooved conveyor belts reduce belt wear and extend service life, while safety interlocks protect operators during machine cycles. The compact footprint—measuring 81″ long by 44″ wide by 71″ tall—makes efficient use of floor space while providing substantial packaging capacity. At 1,271 pounds, this machine offers the stability needed for consistent high-speed operation.

Used Shrink Wrap Equipment Value and Production Efficiency

For manufacturers, distributors, and packaging operations looking to upgrade their shrink wrap capabilities, this 2018 Seal-A-Tron L-Bar Sealer offers proven performance at used equipment pricing. The electronic seal stroke technology and automated conveyor system provide significant productivity advantages over manual or semi-automatic sealers, typically producing 5-15 packages per minute depending on product size and operator efficiency. This automation reduces labor costs, improves package consistency, and increases throughput—delivering rapid return on investment.

The relatively recent manufacture year ensures this machine incorporates modern control technology and reliable electronic components, while the documented cycle count confirms its operational history. Purchasing used shrink wrap equipment from CWR Resources allows you to access industrial-grade packaging capabilities while maintaining healthy cash flow for other operational priorities.

Ready to enhance your shrink wrap packaging efficiency with proven automatic sealing technology? Contact CWR Resources today to discuss how this premium used Seal-A-Tron L-Bar Sealer can transform your packaging operations. Our equipment specialists are standing by to answer your questions and help determine if this machine matches your production requirements.

Details

- Seal Bar Dimensions: 20″ wide x 23″ long (knife edge)

- Maximum Height: 9″ tall

- Web Width: 30″

- Infeed Conveyor: Vinyl belt, 38″ long x 17.75″ wide x 36″ tall

- Discharge Conveyor: Retracting vinyl belt, 36″ long x 17.75″ wide x 36″ tall

- Controls: Panasonic touchscreen with Panasonic AFPX-EFPO PLC

- Machine Cycle Counter: 336,941 cycles

- Construction: Mild steel on casters

- Power Requirements: 208/240V, 1 Phase, 60 Hz, 12 Amp

- Overall Dimensions: 81″ long x 44″ wide x 71″ tall

- Weight: 1,271 lbs

Similar Equipment Listings

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-32811

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-33318

Horizontal Flow Wrappers, Packaging Equipment

-

Eastey Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Packall 48″ Rotary Accumulation Table

Packaging Equipment

-

Mettler Toledo Hi-Speed Beltweigh XC Checkweigher SN 36601261

Checkweighers, Packaging Equipment

-

Lock Met 30+ Metal Detector

Food Metal Detectors, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31899

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31901

Horizontal Flow Wrappers, Packaging Equipment

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging Equipment, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment