Packall 48″ Rotary Accumulation Table

Equipment Specifications

Manufacturer | Packall Inc. |

Model | AT48CS |

Location | North Dakota |

Serial Number | 6241 |

Condition | used |

Rotary Accumulation Table for Packaging Line Flow Management

This used Packall 48″ Rotary Accumulation Table represents an efficient solution for operations seeking to balance production rates and eliminate bottlenecks in their packaging lines. The AT48CS model provides a compact yet effective buffer space that accumulates products, allowing upstream production to continue smoothly when downstream equipment experiences temporary slowdowns or requires manual intervention. Whether positioned at the end of a filling line, between conveyors, or before case packing operations, this rotary table maintains consistent product flow while maximizing limited floor space in your facility.

Used Rotary Accumulation Table with Stainless Steel Construction

Featuring a 48″ diameter overall platform with a 26″ diameter inner ring and 6″ deep accumulation area, this stainless steel accumulation table provides ample capacity for bottles, jars, containers, and packaged products. The food-grade stainless steel construction ensures sanitary operation suitable for food, beverage, pharmaceutical, and consumer goods applications. The durable steel frame mounted on the base provides industrial stability while the compact 48″ x 48″ footprint makes efficient use of valuable production floor space. At 34″ infeed height, this table integrates seamlessly with standard conveyor systems and packaging equipment.

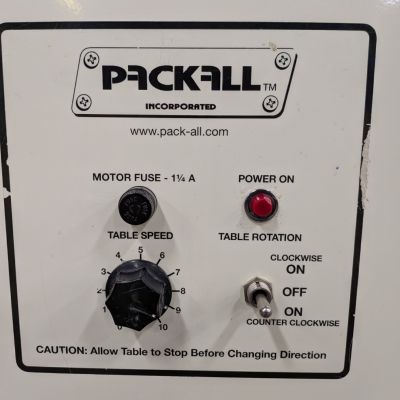

Variable Speed Control for Production Line Efficiency

The integrated variable speed control allows operators to precisely match the table’s rotation speed to their production line pace, ensuring gentle product handling and optimal accumulation performance. This adjustable speed capability prevents product toppling while creating smooth, unrestricted product flow from infeed to discharge. The direct drive motor system provides reliable, maintenance-free operation with minimal wear and tear compared to belt or chain-driven alternatives. At only 120 volts and 1.25 amps, this energy-efficient table operates on standard electrical service without requiring special power accommodations.

Accumulation Conveyors for Bottleneck Prevention

Rotary accumulation tables serve as essential buffering solutions in packaging operations where production speeds vary between processes. When filling equipment operates faster than downstream packaging machinery, this accumulation table collects the excess product on its rotating surface, preventing backups that could halt production. Once the downstream operation catches up, products are gradually released at a controlled rate, maintaining steady workflow throughout the entire line. This buffering capability dramatically reduces downtime and keeps your production schedule on track even when individual machines require adjustments or brief stoppages.

Compact Packaging Equipment for Space-Limited Operations

The circular design of rotary accumulation tables makes them ideal for facilities where end-of-line space is limited. Unlike linear accumulation conveyors that require substantial floor length, this 48″ diameter table provides significant accumulation capacity within a minimal footprint. The rotating platform can be used in conjunction with gravity conveyors, heat tunnels, L-bar sealers, filling equipment, and other packaging machinery to create efficient material handling solutions. Products move toward the center of the table as it rotates, continuously making room for incoming items while maintaining proper orientation for downstream processes.

Used Packaging Automation Equipment Value

For manufacturers, co-packers, and bottling operations looking to improve production flow and reduce bottlenecks, this used Packall rotary accumulation table offers proven performance at accessible pricing. At approximately 217 pounds, this table is substantial enough for industrial reliability yet manageable for repositioning when production layouts change. The stainless steel construction ensures long service life and easy cleaning, while the variable speed control provides the flexibility needed to adapt to different products and line speeds. Investing in used accumulation tables allows you to optimize your packaging line efficiency at a fraction of the cost of new machinery.

Ready to eliminate production bottlenecks and improve packaging line flow with proven accumulation technology? Email CWR Resources today or call 630-262-9595 to discuss how this premium used Packall rotary accumulation table can enhance your packaging operations. Our equipment specialists are standing by to answer your questions and help determine if this machine matches your production requirements.

Details

- Overall Diameter: 48″

- Inner Diameter: 26″

- Depth: 6″

- Infeed Height: 34″

- Speed Control: Variable speed

- Top Material: Stainless steel

- Frame Material: Steel

- Overall Dimensions: 48″ long x 48″ wide x 34″ tall

- Approximate Weight: 217 lbs

- Power Requirements: 120V, 1.25 Amp

Similar Equipment Listings

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-32811

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-33318

Horizontal Flow Wrappers, Packaging Equipment

-

Seal-A-Tron AS-2024-AC Automatic L-Bar Sealer

Packaging Equipment, Shrink Wrap Equipment

-

Eastey Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Mettler Toledo Hi-Speed Beltweigh XC Checkweigher SN 36601261

Checkweighers, Packaging Equipment

-

Lock Met 30+ Metal Detector

Food Metal Detectors, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31899

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31901

Horizontal Flow Wrappers, Packaging Equipment

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging Equipment, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment