Mettler Toledo Hi-Speed Beltweigh XC Checkweigher SN 36601261

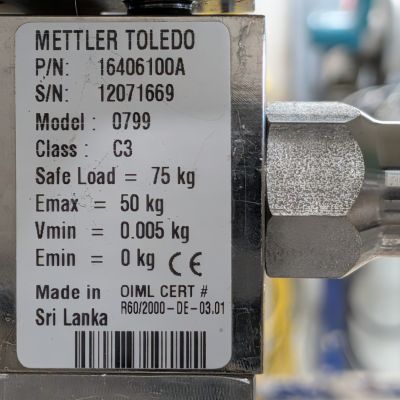

Equipment Specifications

Manufacturer | Mettler-Toledo, LLC |

Model | Beltweigh XC |

Location | North Dakota |

Year | 2018 |

Serial Number | 36601261 |

Condition | used |

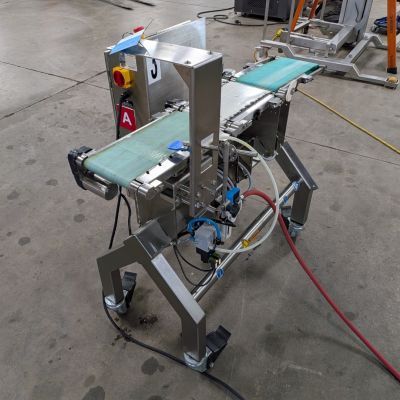

Compact Checkweigher for Space-Limited Production Lines

This used Mettler Toledo Checkweigher Beltweigh XC fits into tight production spaces while delivering full quality control capabilities. Built in 2018, this compact system requires minimal floor space yet handles throughput up to 280 products per minute. The front-mounted control panel keeps operators safe by eliminating the need to reach across conveyors. Maintenance personnel can access all components from one side, reducing downtime during service intervals.

High-Speed Weighing System for Manufacturing Efficiency

Speed matters in production environments. This checkweigher processes products quickly while maintaining accuracy across the 20g to 6000g weighing range. The system catches weight deviations immediately, allowing line operators to correct filling problems before hundreds of bad packages are produced. Fast changeovers between products keep production moving. Simply enter new parameters through the touchscreen and the system is ready for your next SKU.

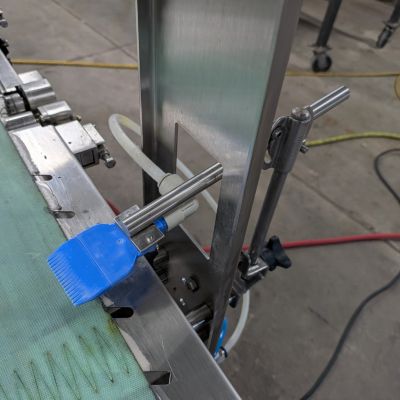

Regulatory Compliance and Brand Protection Equipment

Government regulations require accurate weight labeling on packaged goods. This checkweigher verifies every package meets legal requirements before it ships. The air blast reject system automatically removes non-compliant products, creating documented proof of your quality control process. This protects your company from fines, recalls, and customer complaints. The password-protected controls prevent unauthorized changes to critical weight parameters.

Data Collection for Production Optimization

Modern production management requires real-time information. This checkweigher provides continuous weight data that reveals trends in your filling operations. Spot gradual drift before it causes problems. Track performance across shifts. Identify which products run smoothly and which need attention. The 11-field information display organizes production data clearly for quick operator decisions. This data helps reduce giveaway costs by keeping fills closer to target weights.

All-Welded Stainless Steel Frame Construction

Food processing and wet environments demand durable equipment. The all-welded stainless steel frame withstands washdown procedures and harsh production conditions. FDA-approved materials throughout ensure food safety compliance. The 12″ wide belt accommodates various package sizes from small containers to larger boxes. Locking casters provide mobility for line reconfigurations while maintaining stability during operation. At 308 pounds, this unit stays firmly planted during high-speed weighing cycles.

Cost-Effective Quality Control Investment

Adding automated checkweighing doesn’t require massive capital expenditure. This 2018 Mettler Toledo Checkweigher delivers the same precision weighing as new equipment at a fraction of the cost of new machinery. The XC series provides essential checkweighing features without paying for capabilities your operation doesn’t need. The immediate cost savings and reduced giveaway deliver fast payback.

Ready to implement automated weight verification with reliable Mettler Toledo equipment? Contact CWR Resources today to discuss how this Beltweigh XC Checkweigher can strengthen your quality control program. Our equipment specialists are standing by to answer your questions and help determine if this machine matches your production requirements.

Details

- Conveyor System: 3-conveyor configuration

- Conveyor Dimensions: 17″ long x 8″ wide x 37″ tall (each section)

- Maximum Belt Width: 12″

- Controls: Color touchscreen with XC control system

- Speed Control: Variable/adjustable

- Reject System: Air blast reject

- Weighing Range: 20g to 6000g

- Throughput: Up to 280 products per minute

- Frame Material: Stainless steel with locking casters

- Power Requirements: 110/220V, 1/3 Phase, 50/60 Hz, 8.2 FLA

- Overall Dimensions: 52″ long x 32″ wide x 49″ tall

- Weight: 308 lbs

Similar Equipment Listings

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-32811

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-33318

Horizontal Flow Wrappers, Packaging Equipment

-

Seal-A-Tron AS-2024-AC Automatic L-Bar Sealer

Packaging Equipment, Shrink Wrap Equipment

-

Eastey Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Packall 48″ Rotary Accumulation Table

Packaging Equipment

-

Lock Met 30+ Metal Detector

Food Metal Detectors, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31899

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31901

Horizontal Flow Wrappers, Packaging Equipment

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging Equipment, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment