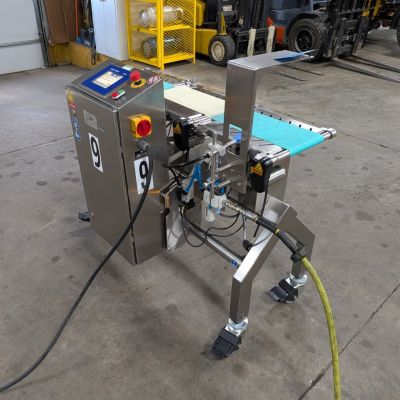

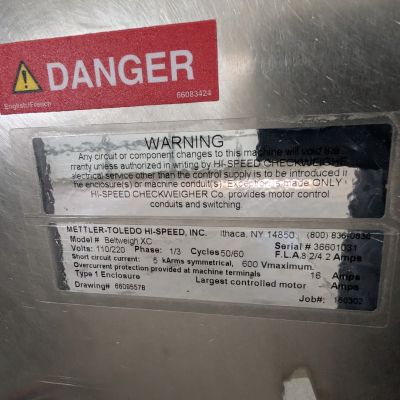

Mettler Toledo Hi-Speed Beltweigh XC Checkweigher SN 36601031

Equipment Specifications

Manufacturer | Mettler-Toledo, LLC |

Model | Beltweigh XC |

Location | North Dakota |

Year | 2018 |

Serial Number | 36601031 |

Condition | used |

Mettler Toledo Checkweigher for Production Line Quality Control

This used Mettler Toledo Checkweigher provides reliable weight verification for production lines. Built in 2018, this system ensures every package meets your weight specifications before it leaves your facility. The XC model delivers the quality control features you need without the complexity of higher-end systems. It’s ideal for operations introducing automated checkweighing or expanding capacity with proven Mettler Toledo technology.

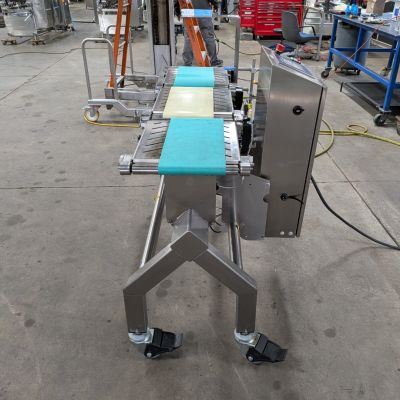

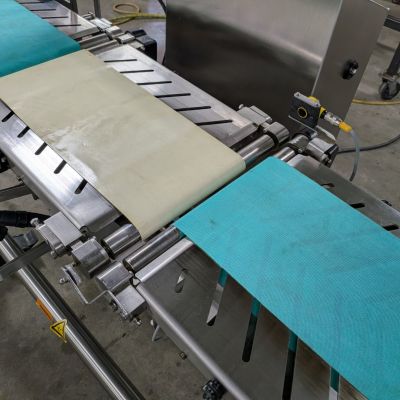

Used Mettler Toledo Checkweigher with 3-Conveyor System

This system includes three conveyor sections working together to move products smoothly through the weighing process. Each section measures 17″ long x 8″ wide x 37″ tall with a maximum belt width of 12″. The infeed conveyor positions products correctly, the weighing section captures precise weight data, and the outfeed conveyor moves products forward or routes rejects out of the line. This three-part design ensures accurate weighing even at high speeds up to 280 products per minute.

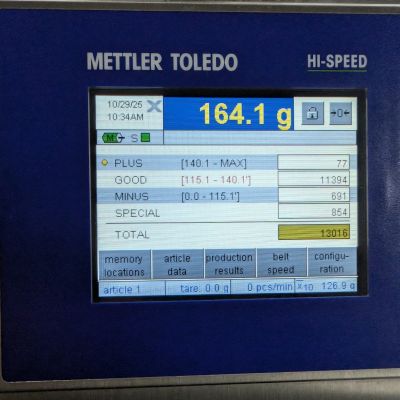

Touchscreen Controls and Air Blast Reject System

The color touchscreen interface makes operation straightforward. Operators can quickly set target weights, adjust parameters, and monitor production data without extensive training. The XC control organizes information clearly across 11 separate fields. Password protection secures setup and configuration menus from unauthorized changes. The integrated air blast reject system automatically removes underweight or overweight products from the line, protecting your brand reputation and ensuring regulatory compliance.

Checkweigher Benefits for Food and Packaging Operations

Checkweighers verify 100% of your production instead of random sampling. This catches filling problems immediately, prevents costly recalls, and keeps underweight packages from reaching customers. The system also prevents giveaway by identifying overweight products that waste expensive ingredients. Real-time weight data helps operators spot trends and make line adjustments quickly. Whether you’re packaging food, pharmaceuticals, or consumer goods, consistent weights build customer trust and meet regulatory requirements.

Stainless Steel Construction and Variable Speed Control

The all-welded stainless steel frame stands up to food processing environments and washdown procedures. Locking casters allow easy repositioning for line changes or maintenance access. The adjustable speed control matches your production pace from slow manual operations to high-speed automated lines. At 308 pounds, this unit provides stable weighing performance while remaining manageable for facility moves. The weighing range from 20 grams to 6000 grams covers most packaged product applications.

Used Checkweigher Equipment Value and Performance

For operations ready to improve quality control, this 2018 Mettler Toledo checkweigher offers proven performance at a fraction of the cost of new machinery. The Beltweigh XC series is built for reliability with features that matter most to production managers: accurate weighing, easy operation, and dependable reject systems. Mettler Toledo’s reputation for precision instrumentation means this equipment will deliver consistent results for years. Investing in used checkweigher equipment lets you protect product quality and regulatory compliance while managing capital budgets effectively.

Ready to upgrade your quality control with proven Mettler Toledo checkweighing technology? Contact CWR Resources today to discuss how this Beltweigh XC checkweigher can improve your packaging operations. Our equipment specialists are standing by to answer your questions and help determine if this machine matches your production requirements.

Details

- Conveyor System: 3-conveyor configuration

- Conveyor Dimensions: 17″ long x 8″ wide x 37″ tall (each section)

- Maximum Belt Width: 12″

- Controls: Color touchscreen with XC control system

- Speed Control: Variable/adjustable

- Reject System: Air blast reject

- Weighing Range: 20g to 6000g

- Throughput: Up to 280 products per minute

- Frame Material: Stainless steel with locking casters

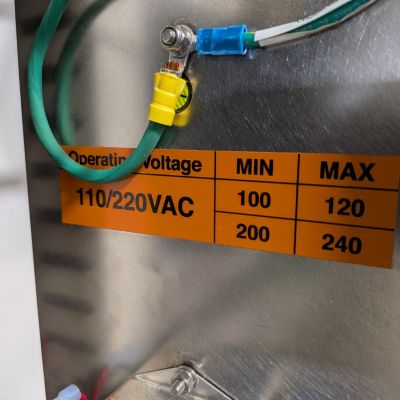

- Power Requirements: 110/220V, 1/3 Phase, 50/60 Hz, 8.2 FLA

- Overall Dimensions: 52″ long x 32″ wide x 49″ tall

- Weight: 308 lbs

Similar Equipment Listings

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-32811

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-33318

Horizontal Flow Wrappers, Packaging Equipment

-

Matrix Bagger Pro Series w/ Weigh Right Linear Scale

Form Fill Seal Machines, Packaging Equipment

-

Seal-A-Tron AS-2024-AC Automatic L-Bar Sealer

Packaging Equipment, Shrink Wrap Equipment

-

Eastey Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Packall 48″ Rotary Accumulation Table

Packaging Equipment

-

Mettler Toledo Hi-Speed Beltweigh XC Checkweigher SN 36601261

Checkweighers, Packaging Equipment

-

Lock Met 30+ Metal Detector

Food Metal Detectors, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31899

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31901

Horizontal Flow Wrappers, Packaging Equipment

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging Equipment, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment