Lock Met 30+ Metal Detector

Equipment Specifications

Manufacturer | Loma Systems |

Model | Met 30+ |

Location | North Dakota |

Year | 2009 |

Serial Number | 41337-1 |

Condition | used |

Metal Detector for Food Safety and Quality Control

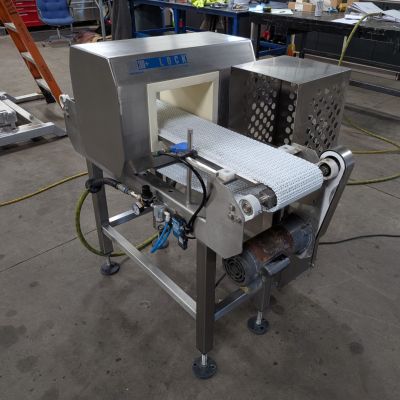

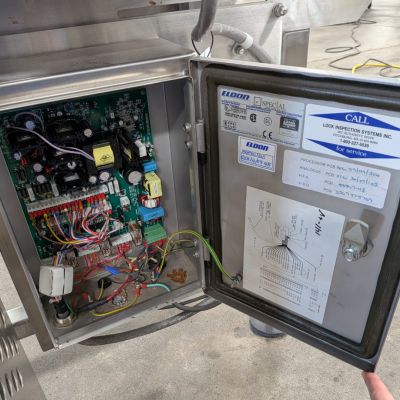

This used Lock Met 30+ Metal Detector provides reliable contamination detection for food processing and packaging operations. Built in 2009 by Lock Inspection (now part of Loma Systems), this system represents proven technology from a manufacturer with over 50 years of metal detection expertise. The Met 30+ was introduced in the late 1990s using digital technology that delivered industry-leading sensitivity. This equipment protects your brand reputation and keeps consumers safe by identifying metal contaminants before products leave your facility.

Used Industrial Metal Detector with Multi-Metal Detection

This system detects all three categories of metal contaminants that matter in food production. Shop testing confirms detection capabilities of 1.5mm for ferrous metals (iron, steel), 1.5mm for non-ferrous metals (aluminum, copper, brass), and 1.5mm for stainless steel 316. Ferrous metals are easiest to detect due to their magnetic properties. Non-ferrous metals are detected through their electrical conductivity. Stainless steel presents the greatest challenge but this system handles all three types effectively. The 9 7/8″ wide by 6 7/8″ tall aperture with 5 1/2″ product clearance accommodates various package sizes and product types.

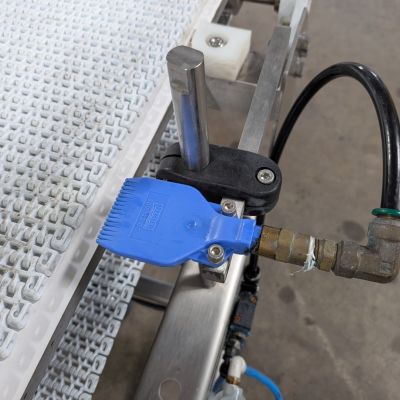

Pneumatic Reject System and Conveyor Integration

The integrated conveyor system moves products through the detection zone at consistent speeds for reliable inspection. The 48″ long by 8″ wide white interlock plastic belt handles packaged and unpackaged products. When the metal detector identifies a contaminant, the pneumatic reject system automatically removes the affected product into the stainless steel reject bin. This automatic rejection ensures contaminated products never continue down the line. The system operates on standard 110V single-phase power, making installation straightforward in most facilities.

Food Metal Detector Compliance and HACCP Programs

Metal detection forms a critical control point in HACCP food safety programs. Government regulations and retailer requirements demand documented contamination control procedures. This metal detector provides verification that your products meet food safety standards including BRC, IFS, and GFSI requirements. Regular testing with calibrated test samples creates the documentation needed for audits and compliance proof. The digital display provides clear operator feedback. Metal contamination can come from processing equipment, packaging machinery, or even raw materials, making end-of-line detection essential.

Stainless Steel Construction for Food Processing Environments

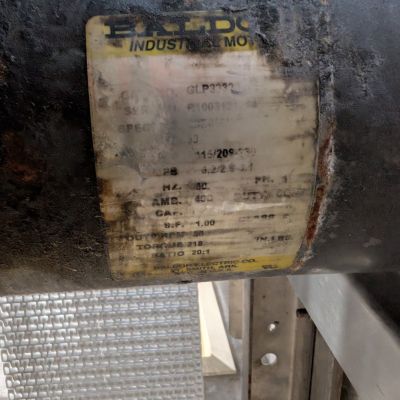

The detector head features stainless steel construction suitable for food contact areas and washdown procedures. The tubular stainless steel frame provides durability in demanding production environments. Adjustable legs allow proper integration with existing conveyor heights and facilitate cleaning underneath the equipment. The Baldor electric motor delivers reliable conveyor operation. At approximately 339 pounds, this unit provides stable operation while remaining manageable for facility moves or line reconfigurations.

Used Metal Detection Equipment Value and Brand Protection

For food processors, co-packers, and packaging operations, metal contamination represents serious risk. Product recalls damage brand reputation and create enormous costs. Consumer injuries from metal fragments lead to liability claims and regulatory action. This 2009 Lock Met 30+ offers proven contamination detection at a fraction of the cost of new machinery. The Lock/Loma heritage means this equipment was built to industrial standards with sensitivity levels that meet food industry requirements. Investing in used metal detection equipment lets you implement critical food safety controls while managing capital budgets effectively.

Ready to strengthen your food safety program with reliable Lock metal detection technology? Contact CWR Resources today to discuss how this Met 30+ metal detector can protect your products and your brand. Our equipment specialists are standing by to answer your questions and help determine if this machine matches your production requirements.

Details

Metal Detector Head

- Aperture: 9 7/8″ wide x 6 7/8″ tall

- Product Clearance: 5 1/2″

- Construction: Stainless steel

Conveyor System

- Belt Type: White interlock plastic belt

- Conveyor Dimensions: 48″ long x 8″ wide x 35.5″ tall

- Frame: Stainless steel tubular construction

- Legs: Adjustable

- Reject System: Pneumatic with stainless steel reject bin

Controls & Electronics

- Display: Digital

- Motor: Baldor electric motor

Performance Verification (Shop Tested)

- Ferrous Detection: 1.5mm

- Non-Ferrous Detection: 1.5mm

- Stainless Steel 316 Detection: 1.5mm

Specifications

- Power Requirements: 110V, 1 Phase, 60 Hz

- Overall Dimensions: 50″ long x 31″ wide x 46″ tall

- Approximate Weight: 339 lbs

Similar Equipment Listings

-

OK International Superformer Case Erector

Case Erectors, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-32811

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-33318

Horizontal Flow Wrappers, Packaging Equipment

-

Seal-A-Tron AS-2024-AC Automatic L-Bar Sealer

Packaging Equipment, Shrink Wrap Equipment

-

Eastey Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Packall 48″ Rotary Accumulation Table

Packaging Equipment

-

Mettler Toledo Hi-Speed Beltweigh XC Checkweigher SN 36601261

Checkweighers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31899

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31901

Horizontal Flow Wrappers, Packaging Equipment

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging Equipment, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment