Eastey Shrink Tunnel

Equipment Specifications

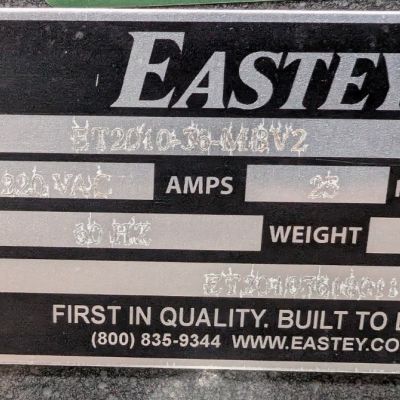

Manufacturer | Eastey/Engage Technologies |

Model | ET2010-36-MBV2 |

Location | North Dakota |

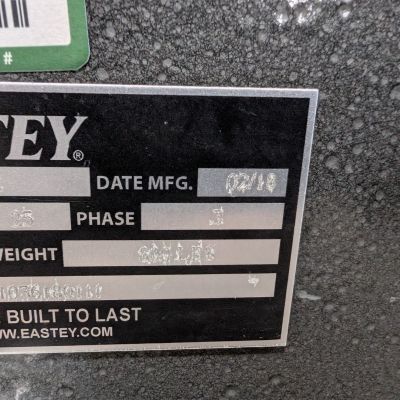

Year | 2018 |

Serial Number | ET201036180111 |

Condition | used |

Professional Heat Shrink Tunnel for High-Volume Packaging Operations

This used Eastey Shrink Tunnel ET2010-36-MBV2 represents an exceptional opportunity for operations seeking to complete their shrink wrap packaging system with proven, reliable heat shrinking technology. Manufactured in 2018 by Eastey/Engage Technologies, a leader in shrink packaging equipment for over 35 years, this Performance Series shrink tunnel delivers consistent, professional results across polyolefin, polyethylene, and PVC shrink films. Built with rugged 12-gauge steel construction, this machine combines industrial durability with the precise temperature control and variable air flow needed for superior shrink packaging results.

Used Shrink Tunnel with Variable Speed Conveyor and Digital Controls

The ET2010-36-MBV2 features a 36″ long tunnel chamber with a 26″ wide aperture (20″ useable width) and 11 3/4″ height clearance, accommodating a wide range of product sizes and packaging configurations. The digital temperature readout provides precise control over the heating process, allowing operators to fine-tune settings for different film types and product requirements. Variable speed conveyor control adjusts product dwell time in the tunnel, ensuring optimal heat exposure for tight, professional shrink results without overheating or film damage. The 48 1/2″ long by 20″ wide conveyor efficiently moves products through the heating chamber for consistent shrinking performance.

Four-Directional Air Flow for Eastey Shrink Wrap Equipment

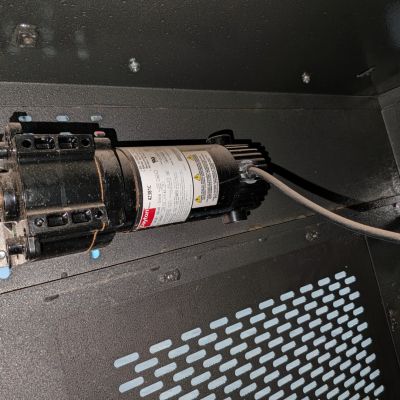

Eastey’s proven four-directional air flow system provides positive shrinking from all sides, eliminating common shrink packaging problems like loose film, wrinkles, or incomplete shrinkage. Variable air flow and air velocity adjustments allow operators to customize the heating pattern for specific products and applications—from delicate items requiring gentle heat distribution to robust packages needing aggressive shrinking. The large ducting creates substantial air volume inside the tunnel chamber, promoting even heat distribution and consistent results. This shrink tunnel equipment is designed to work seamlessly with L-bar sealers, completing an efficient automated shrink wrapping system.

Industrial Shrink Tunnel Construction and Mobility Features

Built with all-welded mild steel construction for long-term industrial reliability, this Eastey shrink tunnel is mounted on heavy-duty casters for easy positioning within your facility. Once positioned, leveling legs provide a stable base for consistent operation. The sealed bearings on drive and idler shafts (not bushings) ensure maintenance-free performance and extended service life. The fold-down electrical control panel facilitates easy maintenance access, while the custom two-part epoxy finish resists scratching in demanding production environments. At approximately 601 pounds, this tunnel provides the stability needed for continuous high-volume operation.

Complete Shrink Packaging Systems and Film Compatibility

This used shrink tunnel is designed to shrink most polyolefin, polyethylene, and PVC shrink films, making it versatile for various packaging applications. Whether you’re packaging food products, consumer goods, industrial components, or retail merchandise, this tunnel delivers the professional finish that enhances product presentation and provides tamper-evident protection. The delayed cool down feature and over-temperature protection safeguard both your products and the machine itself. Conveyor speeds up to 67 feet per minute support high-throughput operations, while the easy-to-use design requires minimal training and maintenance for trouble-free operation.

Used Packaging Equipment Value and ROI

For manufacturers, co-packers, and distribution operations looking to upgrade their shrink packaging capabilities, this 2018 Eastey shrink tunnel offers proven Performance Series quality at used equipment pricing. The relatively recent manufacture year ensures this machine incorporates reliable controls and construction while avoiding the substantial capital investment required for new equipment. Investing in used shrink tunnel equipment allows you to complete or enhance your packaging line while maintaining healthy cash flow for other operational priorities. The Eastey Performance Series reputation for durability and consistent results makes this an intelligent choice for operations ready to automate their heat shrinking process.

Ready to complete your shrink wrap packaging system with proven Eastey technology? Email CWR Resources today or call 630-262-9595 to discuss how this premium used Eastey shrink tunnel can transform your packaging operations. Our equipment specialists are standing by to answer your questions and help determine if this machine matches your production requirements.

Details

- Tunnel Length: 36″

- Conveyor: 48 1/2″ long x 20″ wide x 33″ tall

- Aperture: 26″ wide (20″ useable) x 11 3/4″ tall

- Temperature Control: Digital temperature readout

- Conveyor Speed: Variable speed control

- Construction: Mild steel, on casters

- Overall Dimensions: 49″ long x 37″ wide x 51″ tall

- Approximate Weight: 601 lbs

Similar Equipment Listings

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-32811

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 15-33318

Horizontal Flow Wrappers, Packaging Equipment

-

Seal-A-Tron AS-2024-AC Automatic L-Bar Sealer

Packaging Equipment, Shrink Wrap Equipment

-

Packall 48″ Rotary Accumulation Table

Packaging Equipment

-

Mettler Toledo Hi-Speed Beltweigh XC Checkweigher SN 36601261

Checkweighers, Packaging Equipment

-

Lock Met 30+ Metal Detector

Food Metal Detectors, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31899

Horizontal Flow Wrappers, Packaging Equipment

-

Bosch Pack 201 Horizontal Flow Wrapper SN 13-31901

Horizontal Flow Wrappers, Packaging Equipment

-

Mettler Toledo Safeline X-Ray Inspection System Powerchek+ 400

Food Metal Detectors, Packaging Equipment

-

Adco 15D-105-WD Stainless Steel Semi-Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

FOGG 18-Valve Bottle Filler with 4-Head Plastic Screw Capper

Gravity/Pressure Fillers, Packaging Equipment

-

OK International Case Erector Superformer 1M

Case Erectors, Packaging Equipment

-

CVC Spot or Wrap Around Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

CVC Front & Back Pressure Sensitive Labeler Model 400

Labeling Machines, Packaging Equipment

-

Preferred Packaging Automatic Shrink Tunnel PP181228

Packaging Equipment, Shrink Wrap Equipment

-

ABC Packaging Machine Corp Top Case Taper Model 436T

Case Sealers, Packaging Equipment

-

Langen B-1 Semi Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Kaps-All FS-B Cap Elevator Hopper

Cap Elevators, Packaging Equipment

-

Eastey EM1622T L-Bar Sealer and ET1608 Shrink Tunnel

Packaging Equipment, Shrink Wrap Equipment

-

Viking Masek ST800 Stick Pack Machine

Form Fill Seal Machines, Packaging Equipment

-

Angelus 60L Can Seamer

Can Seamers, Packaging Equipment

-

Econocorp Pegasus Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

Econocorp Spartan Cartoner Horizontal Intermittent

Cartoners, Packaging Equipment

-

Weigh Right Linear Scale

Industrial Scales, Packaging Equipment

-

Shanklin Shrink Wrapper TR1 w/ Shanklin Shrink Tunnel T71

Packaging Equipment, Shrink Wrap Equipment

-

OK International Supertaper Top Case Sealer

Case Sealers, Packaging Equipment

-

OK International Supertaper Bottom Case Taper

Case Sealers, Packaging Equipment

-

Quadrel Moduline 3 Panel Pressure Sensitive Labeler

Labeling Machines, Packaging Equipment

-

Elmar 36-Head Rotary Piston Filler RPE-736/16T w/ 16-Head Capper

Cappers, Filling Machines, Packaging Equipment, Piston Fillers

-

Langen B1-AL Automatic Horizontal Cartoner

Cartoners, Packaging Equipment

-

MCC Wraparound Labeler w/ Top Label Applicator

Labeling Machines, Packaging Equipment

-

Canco Can Seamer Model 08

Can Seamers, Packaging Equipment

-

Bosch Inline Tri-Seal Carton Closer TSC-090

Cartoners, Packaging Equipment

-

Holmatic PR-2S Cup Filler

Cup Fillers, Filling Machines, Packaging Equipment