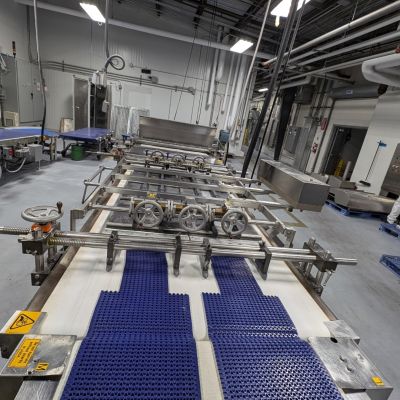

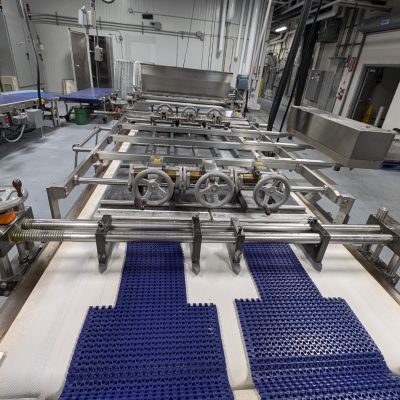

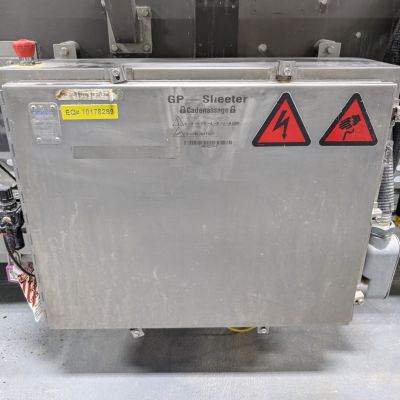

Gemini Two Lane Bread Production Line

Equipment Specifications

Manufacturer | Gemini Bakery Equipment Company |

Model | Complete Bread Line |

Location | North Dakota |

Condition | used |

Efficient and Reliable Industrial Bread Maker

Elevate your bakery’s production capabilities with a used Gemini Two Lane Bread Production Line, a comprehensive commercial bread-making machine designed for efficiency and reliability. This system includes everything needed for streamlined bread production, from dough handling to shaping, making it an ideal solution for high-volume bakeries.

Key Features of this Automatic Bread Production Line

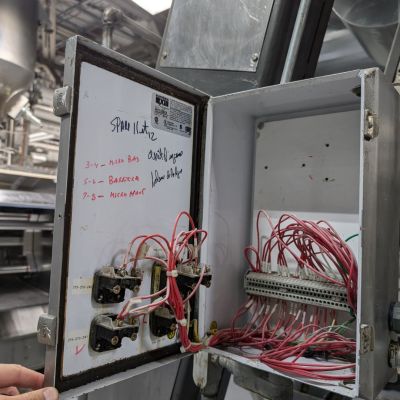

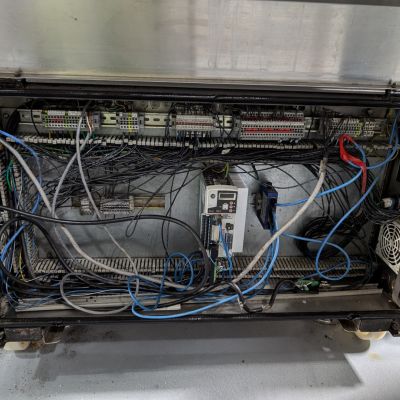

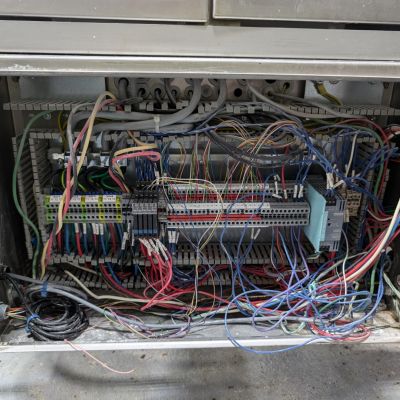

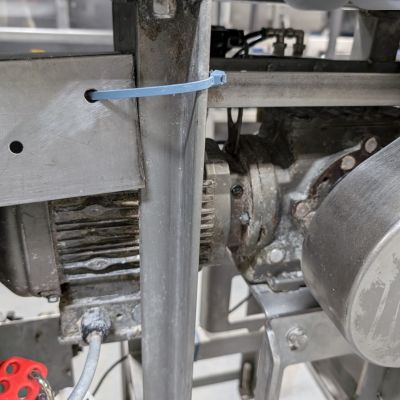

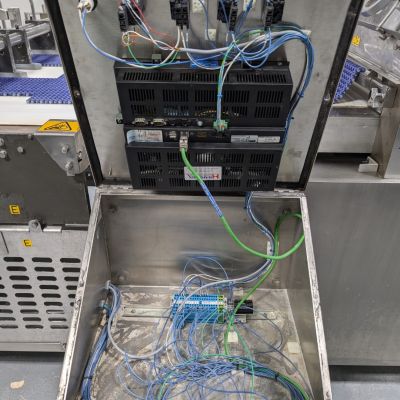

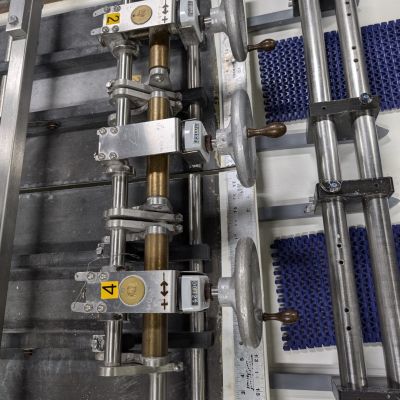

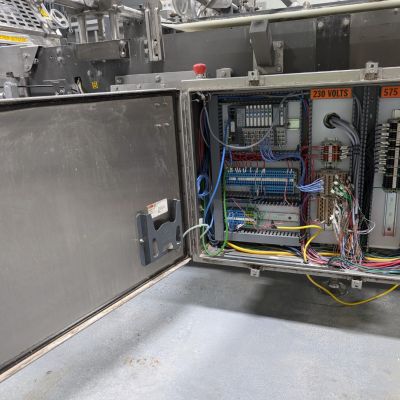

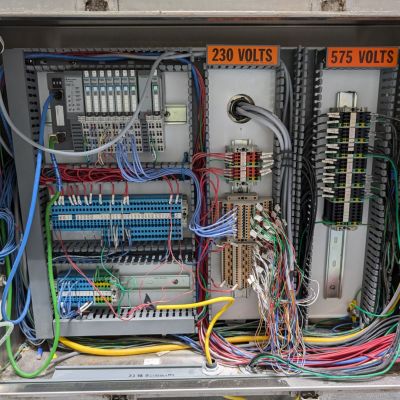

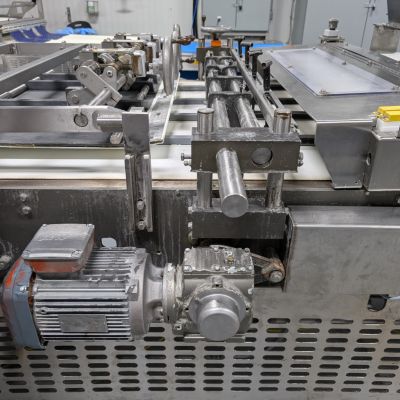

This Gemini bread production line is equipped with state-of-the-art components, including a dual-column tote dumper, Gemini dough chunker, Gemini B-700 divider, and Gemini conical dough rounder. The system features Allen Bradley touchscreen controls and stainless steel construction, ensuring durability and easy operation. With its automated two-lane design, the line offers consistent dough processing, from chunking and dividing to rounding and molding, all while maintaining high production speeds.

Benefits of Investing in a Used Gemini Machine

Purchasing a used Gemini bread production line offers significant cost savings without compromising quality. This machine is designed to handle large-scale production with precision, making it a valuable addition to any bakery operation. The integrated systems technology, including the cleated incline belt conveyors and flour dusters, ensures that each loaf is processed with care, resulting in uniform products that meet the highest standards.

Value and Versatility for Your Bakery

This Gemini Two Lane Bread Production Line is more than just a commercial bread-making machine; it’s a complete solution for enhancing your bakery’s output. Its versatile design allows for the production of various bread types, making it suitable for diverse product lines. Investing in this used bread line means acquiring a proven, reliable system at a fraction of the cost of new equipment. Contact us today to secure this valuable asset for your bakery.

Details

- Dual Column Tote Dumper: 123″ tote dump height, tote max width 52″, tote holes center to center: 30″, mild steel frame, 575V, 3 Phase. Overall dimensions: 81″ W x 59″ L x 178″ T.

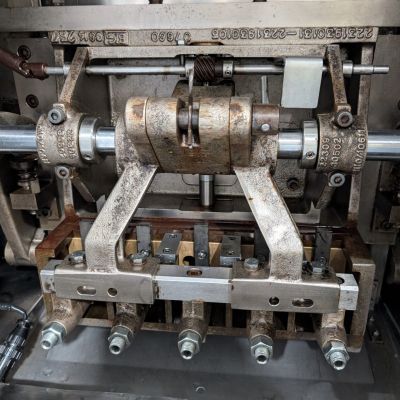

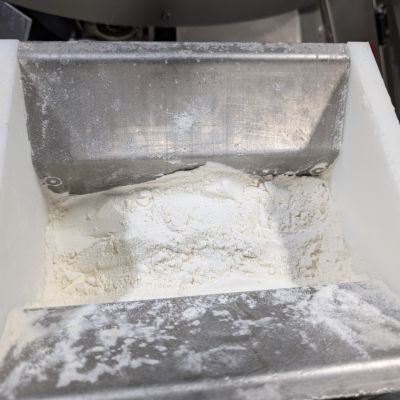

- Gemini Chunker: Teflon-coated hopper, 58″ L x 58″ W x 36″ T, tri-vein rotary cutter, mounted on SS legs.

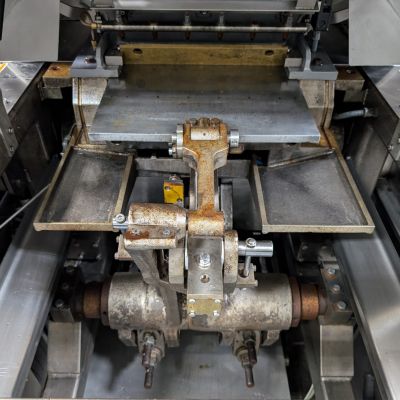

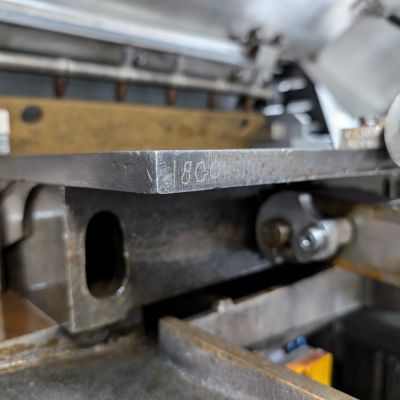

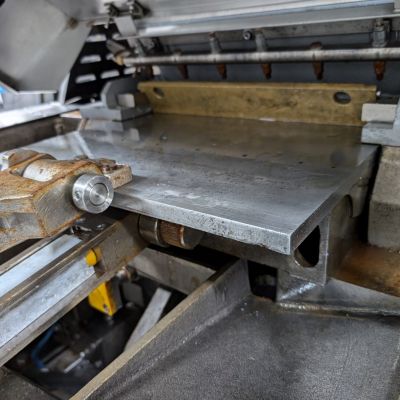

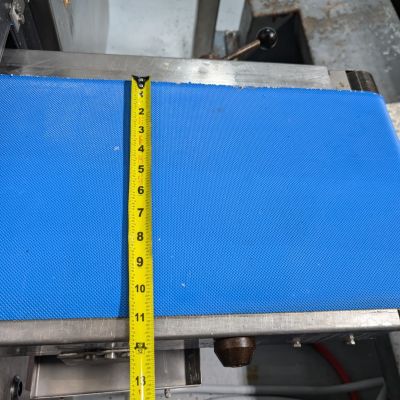

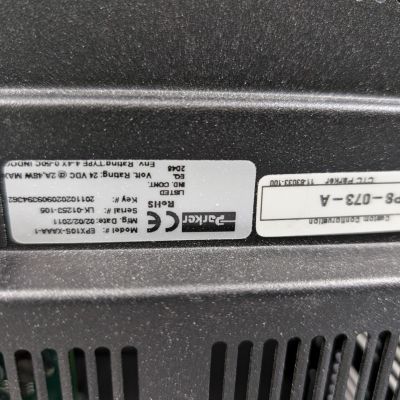

- 2015 Gemini B-700 Divider: Blue rubber belt conveyor 80″ L x 11″ W x 32″ T, Allen Bradley touchscreen controls, Allen Bradley Kinetix 300 VFD, SS construction, 575V, 3 Phase, 60 Hz. Overall dimensions: 80″ L x 70″ W x 70″ T.

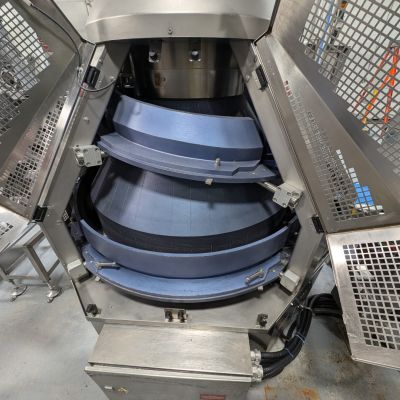

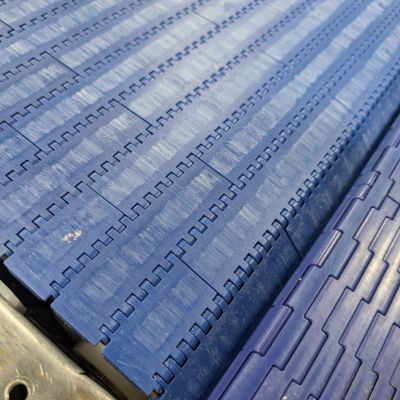

- 2016 Gemini Conical Dough Rounder: Slotted cone, blue rubber infeed conveyor 38″ L x 11″ W x 30″ T, blue rubber discharge conveyor 24″ L x 11″ W x 47.5″ T with flour duster over discharge. SS construction, adjustable legs. Overall dimensions: 103″ L x 72″ W x 70″ T.

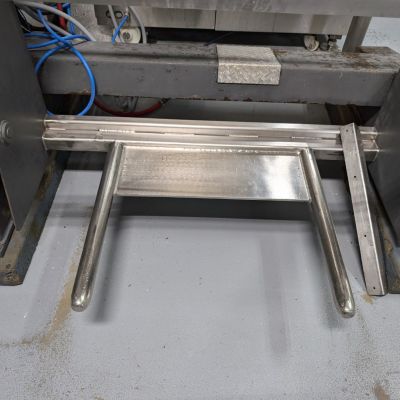

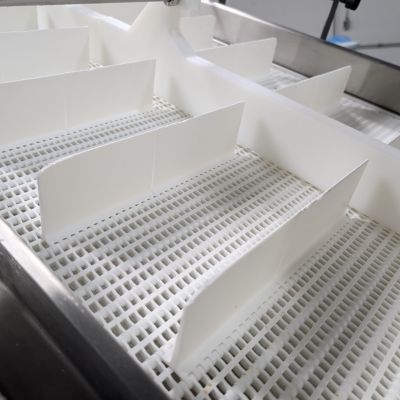

- Tri-Mach Rounder Exit Conveyor: Plastic interlock belt 28″ L x 6″ W x 45″ T, with two-lane SS automatic diverting chute, SS construction, adjustable legs. Overall dimensions: 38″ L x 26″ W x 66″ T.

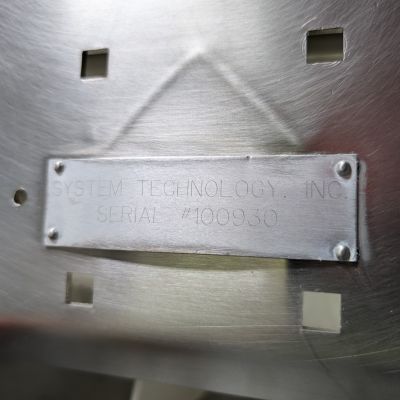

- Systems Technology Cleated Incline Belt Conveyor: 162″ L x 27″ W (each lane 13.5″ W), infeed 23″ T, discharge 77″ T. Cleat spacing 6.25″, cleat height 3″, with SS flour duster and catch trays, SS frame, adjustable legs, on casters. Overall dimensions: 158″ L x 55″ W x 86″ T.

- Overall Footprint of Line: 79′ L x 8.75′ W x 14.8′ T.

- Line Capabilities: Produces 8.5″, 9″, 13″, and 15″ loaves.

- Control: Allen Bradley Panelview 1250 touchscreen control.

Similar Equipment Listings

-

W.C. Smith Cream Beater

Bakery Equipment, Processing Equipment

-

CES Nitrogen Tunnel Freezer

Processing Equipment

-

Hinds Bock Depositor System 5P-32

Bakery Equipment, Processing Equipment

-

AMF Triple Roller Bar Mixer

Mixers/Blenders, Processing Equipment

-

Oliver 777 Variety Bread Slicer (S/N 152052)

Bakery Equipment, Processing Equipment

-

Oliver 777 Variety Bread Slicer (S/N 147560)

Bakery Equipment, Processing Equipment

-

Cretors Seasoning Drum FTSC200-Q2R-PPOM-X

Bakery Equipment, Processing Equipment

-

Stephan Vertical Mixer Cutter UM 74 E

Mixers/Blenders, Processing Equipment

-

Cretors Seasoning Drum FTSC80-A2R-PPOM-M

Bakery Equipment, Processing Equipment

-

Urschel Dicer and Strip Cutter Model J9A

Processing Equipment, Slicers/Dicers

-

Urschel Shredder, Slicer, Strip Cutter Model CC-D

Processing Equipment, Slicers/Dicers

-

Heat & Control Rotary Brander Model RB40

Meat Processing Equipment, Processing Equipment

-

Food Engineering Ltd. Cooling Wheel Drum

Candy Making Equipment, Processing Equipment

-

Russell Compact 600 Sieve w/ Dust Hood & Stand

Processing Equipment, Sifters

-

Roks Montage SS 1/2 Jacketed Cooker Cooler

Processing Equipment, Tanks/Processors

-

Cherry Burrell Stainless Steel Jacketed Paddle Blender/Cooker Cooler

Cooker Coolers, Mixers/Blenders, Processing Equipment, Tanks/Processors

-

Stainless Process Equipment 150 Gallon Stainless Steel Tank

Processing Equipment, Tanks/Processors

-

Alfa Laval Model PX30 Disc Centrifuge

Centrifuges, Processing Equipment

-

Gemini Rotary Dough Chunker

Bakery Equipment, Processing Equipment

-

JH Day Stainless Steel Turbulent Mixer

Mixers/Blenders, Processing Equipment