CES Nitrogen Tunnel Freezer

Equipment Specifications

Manufacturer | CES/DSI DANTECH |

Model | CES-LT-LIN-18ft(2)x11in-HOTL |

Location | North Dakota |

Year | 2015 |

Serial Number | 99239 |

Condition | used |

Used Nitrogen Tunnel Freezer For Sale

This used CES/DSI Dantech liquid nitrogen tunnel freezer represents an exceptional opportunity for food processors seeking to implement or expand cryogenic freezing capabilities. Manufactured in 2015, this industrial freezing system delivers the ultra-fast freezing performance that nitrogen cryogenic tunnels are renowned for, preserving product quality while maximizing throughput. The dual-conveyor configuration provides versatility for processing different product types or running parallel production lines within a single compact footprint.

Cryogenic IQF Technology

Liquid nitrogen tunnel freezers achieve extremely rapid temperature reduction through cryogenic freezing, creating Individual Quick Freezing (IQF) that minimizes ice crystal formation. This method is far faster than traditional mechanical freezing systems, preserving product texture, moisture content, and nutritional value. The result is superior quality that maintains the fresh appearance and taste characteristics your customers expect.

Dual-Conveyor Versatility

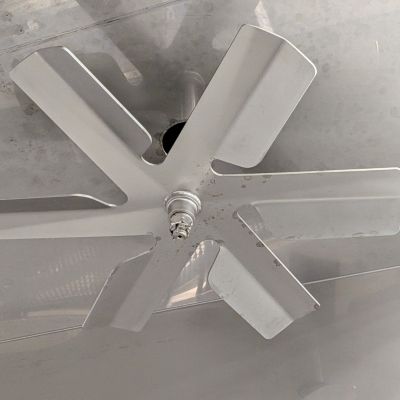

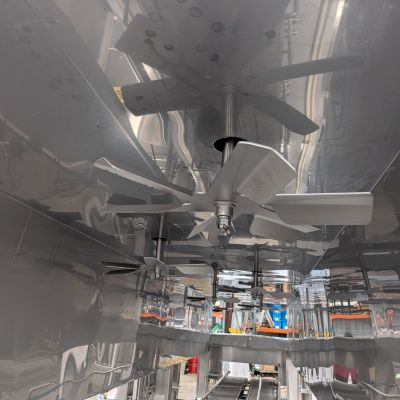

This CES model features an 18-foot freezing chamber equipped with six circulation fans and 48 precisely positioned nitrogen nozzles that ensure uniform temperature distribution throughout the tunnel. The dual stainless steel wire mesh conveyors measure 23′ long by 11″ usable width, with adjustable speed capabilities reaching 68 feet per minute. This configuration allows you to optimize residence time based on product type and desired freezing depth, whether you’re processing delicate berries, formed patties, seafood, pasta, or prepared meals.

Thoughtful Engineering for Food Processing

The dedicated infeed and discharge sections feature protective stainless steel safety hoods for operator safety. Product clearance of 5.75″ accommodates a range of product heights, while the hydraulic raise-and-lower feature simplifies sanitation procedures—a critical consideration in food processing environments. The Allen Bradley variable frequency drives controlling the six freezing chamber fans provide precise airflow management, while the Automation Direct touchscreen interface with Allen Bradley MicroLogix 1400 PLC offers intuitive operation and monitoring.

Premium Value in Used Equipment

Built with full stainless steel construction and mounted on adjustable legs, this nitrogen tunnel freezer combines the durability required for demanding production schedules with the hygienic standards essential in food processing. The independent conveyor controls allow fine-tuning of each belt’s operation, providing flexibility when running different products or adjusting for varying production requirements.

Investing in used cryogenic freezing equipment like this CES liquid nitrogen tunnel provides access to premium IQF technology at a fraction of new equipment costs. The rapid freezing capability, superior product quality preservation, and operational flexibility make this an intelligent choice for food processors looking to enhance their freezing operations.

Ready to explore how this nitrogen tunnel freezer can elevate your food processing capabilities? Contact CWR Resources today to discuss this equipment and determine if it aligns with your production requirements.

Details

- Tunnel Dimensions: 18 ft. freezing chamber; Overall footprint: 28 ft. long x 96 in. wide x 93 in. tall

- Conveyor Specs: (2) SS wire mesh belts: 23 ft. long x 13 in. (11 in. usable) wide x 36 in. tall

- Infeed Section: 33 in. long w/ 32 in. SS safety hood

- Discharge Section: 28 in. long w/ 32 in. SS safety hood

- Product Clearance: 5.75 in.

- Max Conveyor Speed: 68 ft./min.

- Freezing System: (6) freezing chamber fans w/ Allen Bradley VFD controls; 48 nitrogen nozzles

- Exhaust: (2) 12 in. exhaust ports

- Sanitation: Hydraulic raise and lower for cleaning access

- Construction: Stainless steel construction, adjustable legs

- Included: Exhaust piping and nitrogen hoses

- Controls: Automation Direct touchscreen controls; Allen Bradley MicroLogix 1400 PLC; Allen Bradley Powerflex 525 VFDs

- Conveyor Controls: Independent conveyor controls (Controlled separately from the touch screen)

- Control Panels: Machine mounted and stand alone control panels

- Electrical: 460V, 3 Phase, 60 Hz, 29 Amp

Similar Equipment Listings

-

W.C. Smith Cream Beater

Bakery Equipment, Processing Equipment

-

Hinds Bock Depositor System 5P-32

Bakery Equipment, Processing Equipment

-

AMF Triple Roller Bar Mixer

Mixers/Blenders, Processing Equipment

-

Oliver 777 Variety Bread Slicer (S/N 152052)

Bakery Equipment, Processing Equipment

-

Oliver 777 Variety Bread Slicer (S/N 147560)

Bakery Equipment, Processing Equipment

-

Cretors Seasoning Drum FTSC200-Q2R-PPOM-X

Bakery Equipment, Processing Equipment

-

Stephan Vertical Mixer Cutter UM 74 E

Mixers/Blenders, Processing Equipment

-

Cretors Seasoning Drum FTSC80-A2R-PPOM-M

Bakery Equipment, Processing Equipment

-

Gemini Two Lane Bread Production Line

Bakery Equipment, Processing Equipment

-

Urschel Dicer and Strip Cutter Model J9A

Processing Equipment, Slicers/Dicers

-

Urschel Shredder, Slicer, Strip Cutter Model CC-D

Processing Equipment, Slicers/Dicers

-

Heat & Control Rotary Brander Model RB40

Meat Processing Equipment, Processing Equipment

-

Food Engineering Ltd. Cooling Wheel Drum

Candy Making Equipment, Processing Equipment

-

Russell Compact 600 Sieve w/ Dust Hood & Stand

Processing Equipment, Sifters

-

Roks Montage SS 1/2 Jacketed Cooker Cooler

Processing Equipment, Tanks/Processors

-

Cherry Burrell Stainless Steel Jacketed Paddle Blender/Cooker Cooler

Cooker Coolers, Mixers/Blenders, Processing Equipment, Tanks/Processors

-

Stainless Process Equipment 150 Gallon Stainless Steel Tank

Processing Equipment, Tanks/Processors

-

Alfa Laval Model PX30 Disc Centrifuge

Centrifuges, Processing Equipment

-

Gemini Rotary Dough Chunker

Bakery Equipment, Processing Equipment

-

JH Day Stainless Steel Turbulent Mixer

Mixers/Blenders, Processing Equipment